T197A156K015AS Kemet, T197A156K015AS Datasheet - Page 8

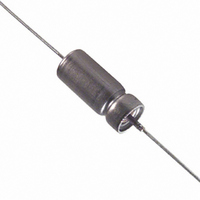

T197A156K015AS

Manufacturer Part Number

T197A156K015AS

Description

CAP TANT-WET 15UF 15V 10% AXIAL

Manufacturer

Kemet

Series

T197r

Type

Hermetically Sealedr

Datasheet

1.T197A566K008AS.pdf

(28 pages)

Specifications of T197A156K015AS

Capacitance

15µF

Voltage - Rated

15V

Tolerance

±10%

Esr (equivalent Series Resistance)

4.420 Ohm

Operating Temperature

-55°C ~ 200°C

Mounting Type

Through Hole

Package / Case

Axial

Size / Dimension

0.219" Dia x 0.453" L (5.56mm x 11.51mm)

Manufacturer Size Code

A

Features

Wet Tantalum

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Height

-

Lead Spacing

-

Other names

399-3406

T197A156K015AS7340

T197A156K015AS7340

8

•

•

c. Test condition letter - H (80G).

d. Duration and direction of motion - 4 hours in

e. Measurements during vibration - During the

f. Examination after test - Capacitors shall be

Shock Test: Per MIL-STD-202, Method 213.

The following details shall apply:

a. Special mounting means - Capacitors shall

b. Test-condition letter - D (500 G peak). 6 ms.

c. Measurements and electrical loading during

d. Examinations after test - Capacitors shall be

Thermal Shock - MIL-STD-202, Method 107:

Capacitors shall be subjected to thermal shock

in accordance with MIL-STD-202, Method 107,

Test Condition A except step 3 shall be +125°C.

Measurements before and after cycling are

required. Conditioning prior to the first cycle will

be 15 minutes at the following standard inspec-

tion conditions:

a. Number of Cycles: 300 for qualification and

b. Ambient Temperature – 25°C ±5°C

c. Final measurements are made after stabi-

each of two mutually perpendicular directions

(total of 8 hours), one parallel and the other

perpendicular to the axis.

last cycle, an electrical measurement shall be

made to determine intermittent operation or

open- or short-circuiting. Observations shall

also be made to determine intermittent con-

tact or arcing or open- or short-circuiting.

Detecting equipment shall be sufficiently sen-

sitive to detect any interruption with a duration

of 0.5 ms, or greater.

• DC Leakage - shall not exceed 1.25 times

• Capacitance - shall not change more than

• DF - shall not exceed 1.15 times initial limit

visually examined for evidence of mechanical

damage.

be rigidly mounted on a mounting fixture by

the body. When securing leads, care shall be

taken to avoid pinching the heads.

(sawtooth)

shock - During the test, observations shall be

made to determine intermittent contact or arc-

ing or open- or short-circuiting. Detecting

equipment shall be sufficiently sensitive to

detect any interruption with a duration of 0.5

ms. The DC rated voltage shall be applied to

the capacitors during the test.

visually examined for evidence of arcing,

breakdown, and mechanical damage.

Group C

lization at room temperature

initial limit

± 5% from initial limit

© KEMET Electronics Corporation, P.O. Box 5928, Greenville, SC 29606 (864) 963-6300

•

•

•

•

•

Moisture Resistance - MIL-STD-202, Method

106: Capacitors shall be tested in accordance

with MIL-STD-202, Method 106 including the

following details:

a. Mounting - The capacitors shall be mounted

b. Initial Measurements

c. Polarizing and Load Voltage - 6 vdc

d. Final measurements - After the final cycle

Resistance to Solvents - MIL-STD-202,

Method 215:

a. Brushing required after test

b. DCL meets limit shown in respective Part

c. Capacitance meets applicable tolerance

d. DF meets limits shown in respective Part

e. No visible damage to case or marking

Resistance to Soldering Heat - MIL-STD-

202, Method 210, Test Condition, Letter C.

Leads shall be immersed to within 0.05 inch of

the capacitor body. Capacitance, DF, and DCL

should meet original limits shown in respective

Part Number Tables.

Solderability - MIL-STD, Method 208:

a. Number of terminations on each capacitor

b. Depth of insertion in flux and solder to with-

Stability at Low and High Temperature

-55°C to 125°C: Capacitors will be capable of

withstanding extreme temperature testing at a

succession of continuous steps at +25°C, -55°C,

+25°C, +85°C, +125°C, +25°C, in the order stated.

Capacitors shall be brought to thermal stability at

each test temperature. Capacitance, DF, and DCL

are measured at each test temperature except that

DCL is not measured at -55°C, DC bias of 2.0 ±0.5

vdc is recommended for the capacitance and DF

measurements.

When measurements are made at the various

steps, the electrical limits for each temperature

shall not exceed the following limits.

Step 1, +25°C

Step 2, -55°C

by normal mounting means

and within 2 to 6 hours after removal of the

capacitors from the humidity chamber, capa-

citance, dissipation factor, and DC leakage

will be measured per MIL-PRF-39006.

Number Tables

Number Tables

tested: 2

in 0.062” of welded joint

DCL as indicated in original

limit; capacitance within toler-

ance specified; DF as indicat-

ed in original limit shown in

Part Number Tables.

Impedance and capacitance

change as defined in M39006

Slash Sheet.