853400-6 Tyco Electronics, 853400-6 Datasheet - Page 5

853400-6

Manufacturer Part Number

853400-6

Description

DIE SET 6POS MOD PLUG OFFSET

Manufacturer

Tyco Electronics

Type

Offset Die Setr

Datasheets

1.1673606-1.pdf

(8 pages)

2.2-231652-0.pdf

(7 pages)

3.853400-1.pdf

(2 pages)

4.853400-1.pdf

(6 pages)

Specifications of 853400-6

Connector Type

Modular Connector, 6 pos

Crimp Handle

A9931-ND (2-231652-0)

Product

Punches & Dies

For Use With

TYCO AMP Modular Plugs

Lead Free Status / RoHS Status

Not applicable / Not applicable

Crimp Or Cable Size

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

A9927

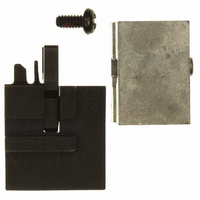

5.3. Replacing or Changing the Die Set

Replace worn die set, or change to another die set as

follows:

Rev D

Fixed Blade

Assembly

Beveled Edges

of Blades Face

Inward

Movable Blade

Assembly

Screw

(2 Places)

3. Install and tighten screws. Adjust cable stripper

according to Paragraph 5.1.

1. Refer to Figure 1 and remove die holding screw.

Slide die indenter and nest out of tool.

2. Insert new die set and secure in place.

NOTE

i

Movable Blade

Assembly

Replacing Blades in Cable Stripper

To order replacement dies, refer to the part

numbers listed in Figure 2 and call

1- - 800- - 526- - 5142.

Adjusting the Cable Stripper

Figure 6

9.7 [.38] (Length)

Screws (2 Places)

6.4 [.25] (Length)

Screw (2 Places)

Cable (Ref)

Movable Blade

Support Plate

Fixed Blade

Support Plate

Blade Set- - Up

Gage (Ref)

Tyco Electronics Corporation

6. MAINTENANCE AND INSPECTION

Inspect the hand tool and die set immediately upon

arrival at your facility and at regularly--scheduled

intervals thereafter to ensure that they have not been

damaged. When not in use, store with tool handles

closed in a clean, dry area.

6.1. Daily Maintenance

At the close of each shift, the responsible operator

should clean foreign particles from the tool using a

soft, clean, lint--free cloth or brush. Make sure all

pins, rings and other retaining hardware is in place,

and that the die set is undamaged. Lightly lubricate all

pins, pivot points and bearing surfaces using a good

grade SAE 20 motor oil. Do not lubricate excessively.

6.2. Periodic Inspection

We recommend that the following inspections be

conducted at least once a month by quality control

personnel. More frequent inspections should be

conducted if your work environment, company

standards, or amount of tool use indicates the need.

A. Visual Inspection

Remove die set from the tool; then, remove all

lubrication and accumulated film and debris by

immersing the dies and tool head in a mild

commercial degreaser.

B. Die Closure Inspection

The hand tool and die set is inspected for correct

operation before shipment. To ensure uniform

performance over the life of the tool, periodically

inspect as follows:

CAUTION

1. Check for missing or defective pins, rings, or

other retaining hardware. Replace parts as

necessary.

2. Closely inspect dies for damage, giving special

attention to bearing surfaces and surfaces that

contact the product. Worn, cracked, pitted, or

chipped indenter or nest surfaces, or other obvious

wear or damage to the die set or tool head requires

removal of the affected part from service.

1. Insert a properly stripped cable of appropriate

type and size into a sample modular plug. Then

insert the unterminated cable and plug into the die

cavity.

2. Squeeze tool handles together slowly, while

watching to ensure indenter bottoms against nest.

!

DO NOT lubricate surfaces of the die set that

contact the product. These areas must be kept

clean to ensure a usable modular plug cable

assembly.

5 of 6