G6H-2-DC24 Omron, G6H-2-DC24 Datasheet - Page 8

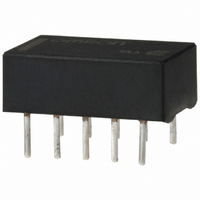

G6H-2-DC24

Manufacturer Part Number

G6H-2-DC24

Description

RELAY MINI PC MNT DPDT 1A 24VDC

Manufacturer

Omron

Series

G6Hr

Specifications of G6H-2-DC24

Coil Type

Standard

Coil Current

8.3mA

Relay Type

Telecom

Circuit

DPDT (2 Form C)

Contact Rating @ Voltage

1A @ 30VDC

Coil Voltage

24VDC

Control On Voltage (max)

18 VDC

Control Off Voltage (min)

2.4 VDC

Mounting Type

Through Hole

Termination Style

PC Pin

Contact Configuration

DPDT

Contact Current Max

1A

Contact Voltage Ac Nom

125V

Contact Voltage Dc Nom

30V

Coil Voltage Vdc Nom

24V

Contact Form

2 Form C

Power Consumption

200 mW

Contact Carry Current

1 A

Maximum Switching Current

1 A

Contact Rating

0.50 A at 125 VAC, 1 A at 30 VDC

Current, Rating

0.5⁄1 AAC⁄ADC

Diameter, Mounting

0.031 in.

Dielectric Rating

1000 VAC

Dimensions

0.551 in. +⁄- 0.008 in. L x 0.354 in. +⁄- 0.008 in. W x 0.197 in. +⁄- 0.008 in. H

Function

Sensitive

Material, Contact

Ag

Number Of Pins

10

Power, Rating

62.5⁄33 VA⁄W

Standards

UL, CSA, RoHS

Temperature, Operating, Maximum

70 °C

Temperature, Operating, Minimum

-40 °C

Voltage, Control

24 VDC

Voltage, Rating

125 VAC

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

G6H2DC24

Z742

Z742

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

G6H-2-DC24V

Manufacturer:

OMRON

Quantity:

12 000

Precautions

Long-term Continuously ON Contacts

Using the Relay in a circuit where the Relay will be ON continuously

for long periods (without switching) can lead to unstable contacts

because the heat generated by the coil itself will affect the insulation,

causing a film to develop on the contact surfaces. We recommend

using a latching relay (magnetic-holding relay) in this kind of circuit. If

a single-side stable model must be used in this kind of circuit, we rec-

ommend using a fail-safe circuit design that provides protection

against contact failure or coil burnout.

Claw Securing Force During Automatic Mounting

During automatic insertion of Relays, be sure to set the securing

force of each claw to the following so that the Relay’s characteristics

will be maintained.

56

Direction A: 1.96 N max.

Direction B: 4.90 N max.

Direction C: 1.96 N max.

A

C

B

Low Signal Relay

G6H

DISCONTINUED

Relay Handling

Use the Relay as soon as possible after opening the moisture-proof

package. If the Relay is left for a long time after opening the mois-

ture-proof package, the appearance may deteriorate and seal failure

may occur after the solder mounting process. To store the Relay after

opening the moisture-proof package, place it into the original pack-

age and seal the package with adhesive tape.

When washing the product after soldering the Relay to a PCB, use a

water-based solvent or alcohol-based solvent, and keep the solvent

temperature to less than 40°C. Do not put the Relay in a cold clean-

ing bath immediately after soldering.