EK29 Cirrus Logic Inc, EK29 Datasheet

EK29

Manufacturer Part Number

EK29

Description

EVAL KIT FOR PWR BOOSTER

Manufacturer

Cirrus Logic Inc

Series

Apex Precision Power™r

Specifications of EK29

Channels Per Ic

1 - Single

Amplifier Type

Power

Output Type

Single-Ended

Board Type

Bare (Unpopulated)

Utilized Ic / Part

PB51

Product

Amplifier Modules

Description/function

Audio Amplifiers

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Operating Temperature

-

Current - Output / Channel

-

Voltage - Supply, Single/dual (±)

-

-3db Bandwidth

-

Slew Rate

-

Current - Supply (main Ic)

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Contains lead / RoHS non-compliant

Other names

598-1466

EK29

EK29

� � � � � � � � � � � � � � �

FLYBACK PROTECTION DIODES

output to both +Vs and to the corresponding Isense pin.

The body diodes of the FETs can be destroyed in specific

circumstances because they cannot be turned “off”, and the

SOA of this portion of the structure is smaller than the SOA

of the switch portion.

dead time between pulses. When the FETs are all turned off

by external control, energy stored in the filter and load must

flow through these diodes. Time constants of this discharge

are often orders of magnitude longer than dead time. If this

action was triggered by a fault detection circuit, energy levels

even higher than normal will have been stored because of the

finite response time of the detection circuit.

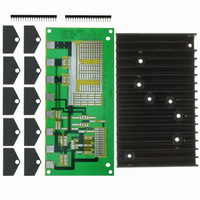

EVALUATION KIT

evaluation. It accommodates only the straight pin version

of the amplifier. The PC board is also a good starting point

for an application specific layout. Provided items include: PC

board, heatsink rated at 1.3°C/W, socket, thermal washers,

ceramic bypass capacitors and two 0.1 ohm current sense

resistors with heatsinks. The amplifier is sold separately.

Common hardware such as screws, nuts and user’s prefer-

ence for I/O connectors are not provided.

HEATSINKS

this amplifier. Thermal ratings are for optimum mounting in

free air.

HS20

board with screws.

HS27 5.3°C/W

board by soldering.

APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

Install a low forward drop, high speed diodes from each

In normal operation, these diodes conduct only during the

EK29 is an easy to use engineering platform for prototype

The following heatsinks are mechanically compatible with

The HS20 is designed to be fastened vertically to a PC

The HS27 is designed to be fastened vertically to a PC

1.3°C/W

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �

AN PB51 REV A DECEMBER 2004 © 2004 Apex Microtechnology Corp.

����������������������������������

���������������������

hole is drilled and deburred. Requirements for the potential

heatsink or chassis member are flatness of 2 mils per inch in

an area large enough to fit the package.

SOCKET

MS06

mounted directly in a print circuit board. Use a spacer between

the PCB and the heatsink to avoid short circuits.

THERMAL WASHER

TW07

NOTES:

1. Base material is aluminum, 0.002” thick. Do not allow the

2. For optimum thermal transfer, avoid abrasive handling of

3. The dry thermal compound will flow filling header to heatsink

4. Do not store unused thermal washers above 40°C.

5. A new washer must be used for each mounting.

6. Part number TW07 consists of a package of 10 washers.

7. Thermal resistance is 0.1°C/W.

Many other heatsinks can be used with this amplifier if a

Part number MS06 consists of 2 socket strips. These are

washer to touch pins of the amplifier.

washers which can damage their 0.5mil thick layer of thermal

compound with which each side is coated.

voids as soon as the material reached 60°C.

1