AD7940-DBRD Analog Devices Inc, AD7940-DBRD Datasheet - Page 19

AD7940-DBRD

Manufacturer Part Number

AD7940-DBRD

Description

BOARD EVAL FOR AD7940 STAMP SPI

Manufacturer

Analog Devices Inc

Datasheet

1.AD7940BRJZ-REEL7.pdf

(20 pages)

Specifications of AD7940-DBRD

Number Of Adc's

1

Number Of Bits

14

Sampling Rate (per Second)

100k

Data Interface

Serial

Inputs Per Adc

1 Single Ended

Input Range

0 ~ Vdd

Power (typ) @ Conditions

17mW @ 100kSPS & 5 V

Voltage Supply Source

Single Supply

Operating Temperature

-40°C ~ 85°C

Utilized Ic / Part

AD7940

Lead Free Status / RoHS Status

Lead free / RoHS non-compliant

APPLICATION HINTS

GROUNDING AND LAYOUT

The printed circuit board that houses the AD7940 should be

designed such that the analog and digital sections are separated

and confined to certain areas of the board. This facilitates the

use of ground planes that can be separated easily. A minimum

etch technique is generally best for ground planes, since it gives

the best shielding. Digital and analog ground planes should be

joined at only one place. If the AD7940 is in a system where

multiple devices require an AGND to DGND connection, the

connection should still be made at one point only, a star ground

point that should be established as close as possible to the AD7940.

Avoid running digital lines under the device since these will

couple noise onto the die. The analog ground plane should be

allowed to run under the AD7940 to avoid noise coupling. The

power supply lines to the AD7940 should use as large a trace as

possible to provide low impedance paths and reduce the effects

of glitches on the power supply line. Fast switching signals, such

as clocks, should be shielded with digital ground to avoid radi-

ating noise to other sections of the board, and clock signals

should never be run near the analog inputs. Avoid crossover of

digital and analog signals. Traces on opposite sides of the board

should run at right angles to each other, which will reduce the

effects of feedthrough through the board. A microstrip tech-

nique is by far the best but is not always possible with a double-

sided board. In this technique, the component side of the board

is dedicated to ground planes while the signals are placed on the

solder side.

Rev. 0 | Page 19 of 20

Good decoupling is also very important. All analog supplies

should be decoupled with 10 µF tantalum in parallel with 0.1 µF

capacitors to AGND, as discussed in the Typical Connection

Diagram section. To achieve the best performance from these

decoupling components, the user should attempt to keep the

distance between the decoupling capacitors and the V

GND pins to a minimum, with short track lengths connecting

the respective pins.

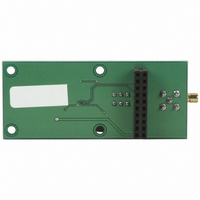

EVALUATING THE AD7940 PERFORMANCE

The recommended layout for the AD7940 is outlined in the

evaluation board for the AD7940. The evaluation board package

includes a fully assembled and tested evaluation board, docu-

mentation, and software for controlling the board from the PC

via the evaluation board controller. The evaluation board con-

troller can be used in conjunction with the AD7940 evaluation

board, as well as many other Analog Devices evaluation boards

ending in the CB designator, to demonstrate/evaluate the ac and

dc performance of the AD7940.

The software allows the user to perform ac (fast Fourier trans-

form) and dc (histogram of codes) tests on the AD7940. The

software and documentation are on a CD shipped with the

evaluation board.

AD7940

DD

and