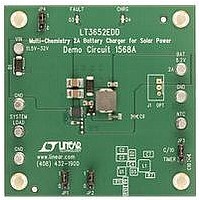

DC1568A Linear Technology, DC1568A Datasheet - Page 2

DC1568A

Manufacturer Part Number

DC1568A

Description

BOARD BATTERY CHARGER SOLAR PWR

Manufacturer

Linear Technology

Datasheet

1.DC1568A.pdf

(6 pages)

Specifications of DC1568A

Main Purpose

Power Management, Battery Charger

Embedded

No

Utilized Ic / Part

LT3652

Primary Attributes

Multi-Chemistry, Solar Power

Secondary Attributes

LED Status Indicators

Silicon Manufacturer

Linear Technology

Silicon Core Number

LTC3652

Kit Application Type

Power Management - Battery

Application Sub Type

Battery Charger

Development Tool Type

Hardware - Eval/Demo Board

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

LT3652EDD

rent is set using an external inductor current sense resis-

tor. A maximum charge current programming pin allows

dynamic manipulation of the battery charge current. The

LT3650 also incorporates a system input-supply current

limit control feature that servos the battery charge cur-

rent to accommodate overall system load requirements.

The LT3652 automatically enters a battery precondition

mode if the sensed battery voltage is very low. In this

mode, the charging current is reduced to 15% of the

programmed maximum, as set by the inductor sense

resistor, R

internally set threshold of 5.7V / cell, the IC automatically

increases maximum charging current to the full pro-

grammed value.

The LT3652 can use a charge-current based ‘C/10’ ter-

mination scheme, which ends a charge cycle when the

battery charge current falls to 1/10

maximum charge current. The LT3652 also contains an

internal charge cycle control timer, for timer-based ter-

mination. When using the internal timer, the IC com-

bines C/10 detection with a programmable time con-

straint, during which the charging cycle can continue

beyond the C/10 level to “top-off” a battery. The charge

cycle terminates when a specific time elapses, typically 3

QUICK START PROCEDURE

Demonstration circuit 1568A is easy to set up to evaluate

the performance of the LT3652EDD.

Using short twisted pair leads for any power connec-

tions, with all loads and power supplies off, refer to

Figure 1 for the proper measurement and equipment

setup.

Follow the procedure below:

1. Jumper and Power Supply Setting:

2

JP1 = 1

JP2 = 1

JP3 = C/10

SENSE

. Once the battery voltage climbs above an

JP4 = 1

PS1 = OFF

PS2 = OFF

th

the programmed

hours. When the timer-based scheme is used, the IC

also supports ‘bad-battery’ detection, which triggers a

system fault if a battery stays in precondition mode for

more than 1/8

Once charging is terminated and the LT3652 is not ac-

tively charging, the IC automatically enters a low-current

standby mode where supply bias currents are reduced to

< 100uA. If the battery voltage drops 2.5% from the full-

charge float voltage, the LT3652 engages an automatic

charge cycle restart. The IC also automatically restarts a

new charge cycle after a bad battery fault once the failed

battery is removed and replaced with another battery.

The LT3652 includes provisions for a battery tempera-

ture monitoring circuit. This feature monitors battery

temperature during the charging cycle using a thermis-

tor, and suspends charging and signals a fault condition

if the battery temperature moves outside a safe charging

range of 0

The LT3652 contains two digital open-collector outputs,

which provide charger status and signal fault conditions.

These binary-coded pins signal battery charging, standby

or shutdown modes, battery temperature faults, and bad

battery faults.

2. Turn on PS2 and slowly increase the voltage to

3. Verify that the battery charging current, IBAT, is

4. Increase PS2 until VBAT is 7.2V. Verify the input

5.4V while monitoring the current into the BAT

pin. If the current is less than 5mA, turn on PS1.

Increase the voltage on PS1 to 5V while monitor-

ing the input current. If the current is less than

5mA, increase PS1 to 12V.

between 250mA and 350mA. The CHRG LED

should be on and the FAULT LED should be off.

current, IIN, is between 1.3A and 1.7A, the battery

current, IBAT, is between 1.775A and 2.225A and

that the CHRG LED is on.

O

C to 50

th

of the total charge cycle time.

O

C.