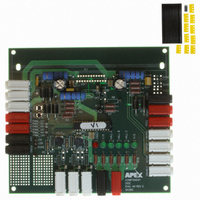

DB62 Cirrus Logic Inc, DB62 Datasheet

DB62

Specifications of DB62

Related parts for DB62

DB62 Summary of contents

Page 1

... The stator windings are energized in a sequence based upon the combination of three Hall sensor signals which provide the rotor position. In the DB62 the SA305 input PWM control is achieved by means on-board Microchip® PIC 18F2331 microcontroller. The sequence table for com- ...

Page 2

... DB62 Figure 1: Algorithm for Microchip® PIC 18F2331 MCU as implemented for DB62. APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739 2 EVALUATION KIT FOR SA305EX ...

Page 3

... D1-D6 (2 for each output provided with DB62) are recommended for use as external flyback diodes because of superior reverse recovery characteristics. Please note that in the DB62, jumpers are needed in order to con- nect the external schottky diodes (see EVAL49 layout). b) External RC snubber circuits (R13 and C5, R16 and C8, R19 and C10 in EVAL49 schematic) can provide noise immunity especially in high load current scenarios ...

Page 4

... The SA305 requires an external reset pulse at the disable pin to resume normal operation when the part latched fault condition because of Short-circuit, Over Temperature (>160°C) or Over-Current (>10 A). In the DB62 board, there is a provision to reset the part automatically without human intervention. A jumper needs to be connected between J1A and P11 of MCU as shown in the schematic ...

Page 5

... EVALUATION KIT FOR SA305EX EVAL49 SCHEMATIC APEX MICROTECHNOLOGY CORPORATION • TELEPHONE (520) 690-8600 • FAX (520) 888-3329 • ORDERS (520) 690-8601 • EMAIL prodlit@apexmicrotech.com DB62 5 ...

Page 6

... APEX MICROTECHNOLOGY CORPORATION • 5980 NORTH SHANNON ROAD • TUCSON, ARIZONA 85741 • USA • APPLICATIONS HOTLINE: 1 (800) 546-2739 This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice. 6 DB62U REV B OCTOBER 2006 © 2006 Apex Microtechnology Corp.. EVALUATION KIT FOR SA305EX ...