INTRODUCTION

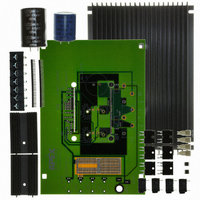

of PWM circuits using the MSA240KC/260KC pin out. With

ample bread boarding areas it is flexible enough to analyze

a multitude of standard or proprietary circuit configurations.

Critical connections for power supply bypassing are pre-wired.

Components not usually readily available in engineering labs

are provided. External connection to the evaluation kit can be

made via the terminal block and banana jacks at the edges

of the circuit board.

BEFORE YOU GET STARTED

• All A pex Precision Power amplifiers should be handled using

• Do not change connections while the circuit is powered.

• Initially set all power supplies to the minimum operating

PARTS LIST

Ref

NA

NA

NA

NA

NA

BJ1-4

C1,3

For identification note this capacitor has “legs” .

C2*

C2*

TS1

R1,2*

R1,2*

R1,2*

*Chosen per directions

ASSEMBLY

product you are using, either the MSA240KC or MSA260KC.

1. Note that each side of the circuit board is identified as either

EK56U

This easy-to-use kit provides a platform for the evaluation

During assembly refer to Figure 1 and the data sheet for the

proper ESD precautions.

voltage allowed in the device data sheet.

the component side or "DUT side".

Evaluation Kit for MSA240KC and MSA260KC

http://www.cirrus.com

Apex Part No.

HS28

HS26

MS11

EVAL56

60SPG00004

BJ1

ZX7R105KTL

EC05

EC06

TS02

CSR22

CSR20

CSR21

EK56 MSA240, MSA260

P r o d u c t I n n o v a t i o n F r o m

P r o d u c t I n n o v a t i o n F r o m

Description/Vendor

Heat Sink,

Apex Precision Power

Heat Sink,

Apex Precision Power

30-pin socket carrier strip

PC Board

Spacer Grommets/

Micro Plastics

Banana Jack/

Deltron 164-6218

1uf 500V Cap/

Novacap

ST2225B105K501LLXW

2200uF 100V/

United Chemi-Con

82DA222M100KC2D

470uF 450V/

United Chemi-Con

KMH450VN471M35X50T2

Terminal Strip

0.020Ω Resistor/

Isotek PBV-R020-1

0.010Ω Resistor/

Isotek PBV-R010-1

0.015Ω Resistor/2

Isotek PBV-R015-1

Copyright © Cirrus Logic, Inc. 2009

(All Rights Reserved)

Qty

2

1

2

1

4

4

2

1

1

1

2

2

2. Two 30-pin socket strips have been supplied with this kit

3. Solder the surface mount capacitors at C1 and C3 on the

4. From the "component side" mount banana jacks at BJ1-4

5. Several low ohm value resistors are provided with this evalu-

6. From the "component side" of the PCB mount the HS28

7. Apply a thin layer of thermal grease on the back of the

8. Mount the remaining HS28 heat sink similarly to step 6.

9. Repeat step 7 for R1 and the second HS28 heat sink.

10. Mount the electrolytic capacitor at C2 from the "compo-

11. Mount the terminal strip to the "component side" of the

12. Mount a BNC connector (not supplied) to the PCB at loca-

13. Mount other components to complete your application

It is therefore convenient to use 3 resistors of equal value

that have been loaded with cage jacks. Using wire cutters

trim the carrier to remove two sockets from one of the strips.

Insert the socket strips from the "DUT side" of the board and

solder the jacks from the "component side" of the board,

making sure that each socket strip is fully seated before

soldering. After soldering the jacks remove and discard

the plastic carrier.

"component side" of the board.

and solder from the "DUT Side" of the circuit board. Cut

off excess lead lengths. Note that BJ1 is connected to SIG

GND.

ation kit: 0.020Ω, 0.015Ω and 0.010Ω. These are used to

implement current limiting in the output circuit. Select the

value most appropriate for your application. Refer to the

product data sheet to determine which resistor value you

should use.

heat sink closest to C2 (to be added later) and solder the

mounting tabs of the heat sink from the "DUT side" with a

high capacity soldering iron.

chosen current limiting sense resistor R2 and insert the

resistor into the PCB. Mount the resistor to the HS28 heat

sink using #4 screw and nut hardware (not supplied). Place

the screw into the mounting hole from the narrow-channel

side of the heat sink and place the nut on the screw from

the wide-channel side of the heat sink. Do not over tighten

the screw. Finally, solder the resistor terminals to the PCB

and cut off the excess lead length.

nent side" of the PCB. Match the polarity markings on the

capacitor with the polarity markings on the PCB. Use the

correct voltage capacitors for the product you are using:

A 100V capacitor for the MSA240KC, or a 450V capacitor

for the MSA260KC. Be sure the capacitors have snapped

into the PCB and solder from the "DUT side" of the PCB.

Be sure to fill the holes with solder.

PCB. Make sure the terminal strip is fully seated and solder

the pins from the "DUT side" of the PCB. Be sure to fill the

mounting holes with solder.

tion 5 (near the banana jacks) if desired. The body of the

BNC connector is tied to SIG GND.

circuit using the pads and holes provided. Refer to the data

sheet for your model and note on page 4 that:

and make up R

the PCB locations for R

RAMP

R

RAMP

from two of those resistors. Note on

RAMP1

= 2 X R

and R

OSC

APEX − EK56UREVJ

RAMP2

to do this.

EK56

MAY 2009

EK56

1