UQQ-3.3/25-Q48NB-C Murata Power Solutions Inc, UQQ-3.3/25-Q48NB-C Datasheet - Page 13

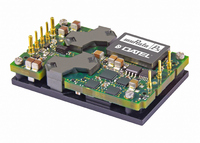

UQQ-3.3/25-Q48NB-C

Manufacturer Part Number

UQQ-3.3/25-Q48NB-C

Description

CONV DC/DC 82.5W 25A 3.3V T/H

Manufacturer

Murata Power Solutions Inc

Series

UQQr

Type

Isolatedr

Datasheet

1.UQQ-128-Q12PB-C.pdf

(18 pages)

Specifications of UQQ-3.3/25-Q48NB-C

Output

3.3V

Number Of Outputs

1

Power (watts)

82W

Mounting Type

Through Hole

Voltage - Input

18 ~ 75V

Package / Case

8-DIP Module, 1/4 Brick

1st Output

3.3 VDC @ 25A

Size / Dimension

2.22" L x 1.45" W x 0.50" H (56.4mm x 36.8mm x 12.7mm)

Power (watts) - Rated

82.5W

Operating Temperature

-40°C ~ 85°C

Efficiency

88%

Approvals

CSA, cUL, EN, UL

Output Type

Quarter-Brick

No. Of Output Channels

1

Input Voltage

18V To 75V

Power Rating

82.5W

Output Voltage

3.3V

Output Current

25A

Supply Voltage

48V

Dc / Dc Converter Case

RoHS Compliant

Dc / Dc Converter O/p Type

Quarter-Brick

No. Of Outputs

1

Rohs Compliant

Yes

Product

Isolated

Output Power

83 W

Input Voltage Range

18 V to 75 V

Input Voltage (nominal)

48 V

Output Voltage (channel 1)

3.3 V

Output Current (channel 1)

25 A

Isolation Voltage

2.25 KV

Package / Case Size

Quarter Brick

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3rd Output

-

2nd Output

-

4th Output

-

Lead Free Status / Rohs Status

Details

Other names

811-1891-5

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Part Number:

UQQ-3.3/25-Q48NB-C

Manufacturer:

MURATA/村田

Quantity:

20 000

Soldering Guidelines

Murata Power Solutions recommends the specifi cations below when installing these

converters. These specifi cations vary depending on the solder type. Exceeding these

specifi cations may cause damage to the product. Your production environment may dif-

fer; therefore please thoroughly review these guidelines with your process engineers.

Removal of Soldered UQQ’s from Printed Circuit Boards

Should removal of the UQQ from its soldered connection be needed, thor-

oughly de-solder the pins using solder wicks or de-soldering tools. At no time

should any prying or leverage be used to remove boards that have not been

properly de-soldered fi rst.

Input Source Impedance

UQQ converters must be driven from a low ac-impedance input source. The

DC/DC’s performance and stability can be compromised by the use of highly

inductive source impedances. The input circuit shown in Figure 2 is a practical

solution that can be used to minimize the effects of inductance in the input

traces. For optimum performance, components should be mounted close to the

DC/DC converter.

I/O Filtering, Input Ripple Current, and Output Noise

All models in the UQQ Series are tested/specifi ed for input ripple current (also

called input refl ected ripple current) and output noise using the circuits and

layout shown in Figures 2 and 3. External input capacitors (C

serve primarily as energy-storage elements.

For Sn/Ag/Cu based solders:

Maximum Preheat Temperature

Maximum Pot Temperature

Maximum Solder Dwell Time

Technical Notes

Wave Solder Operations for through-hole mounted products (THMT)

V

OSCILLOSCOPE

IN

+

–

C

C

L

TO

BUS

IN

BUS

= 33μF, ESR < 700mΩ @ 100kHz

= 12μH

= 220μF, ESR < 100mΩ @ 100kHz

Figure 2. Measuring Input Ripple Current

C

BUS

L

BUS

115° C.

270° C.

7 seconds

CURRENT

PROBE

C

IN

For Sn/Pb based solders:

Maximum Preheat Temperature

Maximum Pot Temperature

Maximum Solder Dwell Time

3

1

+INPUT

–INPUT

IN

in Figure 2)

www.murata-ps.com

105° C.

250° C.

6 seconds

They should be selected for bulk capacitance (at appropriate frequencies),

low ESR, and high rms-ripple-current ratings. The switching nature of

DC/DC converters requires that dc voltage sources have low ac impedance as

highly inductive source impedance can affect system stability. In Figure 2,

C

fi guration may necessitate additional considerations.

In critical applications, output ripple/noise (also referred to as periodic

and random deviations or PARD) can be reduced below specifi ed limits

using fi ltering techniques, the simplest of which is the installation of

additional external output capacitors. Output capacitors function as true

fi lter elements and should be selected for bulk capacitance, low ESR, and

appropriate frequency response. In Figure 3, the two copper strips simulate

real-world pcb impedances between the power supply and its load. Scope

measurements should be made using BNC connectors or the probe ground

should be less than ½ inch and soldered directly to the fi xture.

All external capacitors should have appropriate voltage ratings and be

located as close to the converter as possible. Temperature variations for all

relevant parameters should be taken into consideration. OS-CON

semiconductor capacitors (www.sanyo.com) can be especially effective for

further reduction of ripple/noise. The most effective combination of external

I/O capacitors will be a function of line voltage and source impedance, as

well as particular load and layout conditions.

Wide Input Range Single Output DC/DC Converters

BUS

and L

BUS

+OUTPUT

–OUTPUT

+SENSE

simulate a typical dc voltage bus. Your specifi c system con-

–SENSE

Figure 3. Measuring Output Ripple/Noise (PARD)

C1 = 1μF CERAMIC

C2 = 10μF TANTALUM

LOAD 2-3 INCHES (51-76mm) FROM MODULE

7

8

4

5

C1

COPPER STRIP

COPPER STRIP

25 Mar 2011 MDC_UQQ.B01 Page 13 of 18

C2

email: sales@murata-ps.com

UQQ Series

SCOPE

TM

R

LOAD

organic