HFBR-1532Z Avago Technologies US Inc., HFBR-1532Z Datasheet - Page 3

HFBR-1532Z

Manufacturer Part Number

HFBR-1532Z

Description

XMITTER FIBER OPTIC VERT 1MBD

Manufacturer

Avago Technologies US Inc.

Specifications of HFBR-1532Z

Wavelength

600nm

Voltage - Forward (vf) Typ

2.02V

Current - Dc Forward (if)

1A

Voltage - Dc Reverse (vr) (max)

5V

Capacitance

86pF

Connector Type

Versatile Link

Function

Ideal for solving problems with voltage isolation/insulation, EMI/RFI immunity or data security.

Product

Transmitter

Data Rate

5 MBd

Diode Capacitance

86 pF

Maximum Rise Time

80 ns (Typ)

Maximum Fall Time

40 ns (Typ)

Pulse Width Distortion

30 ns

Maximum Output Current

5.1 mA

Operating Supply Voltage

7 VDC

Maximum Operating Temperature

+ 85 C

Minimum Operating Temperature

- 40 C

Data Rate Max

4Mbps

Forward Current If

80mA

Forward Voltage

1.67V

Reverse Voltage Vr

5V

Data Transmission Distance

55ft

Wavelength Typ

660nm

Msl

MSL 4 - 72 Hours

Fiber Material

Plastic

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Spectral Bandwidth

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

For Use With

Plastic Optical Fiber

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-2049

Handling

Versatile Link components are auto-insertable. When

wave soldering is performed with Versatile Link compo-

nents, the optical port plug should be left in to prevent

contamination of the port. Do not use reflow solder

processes (i.e., infrared reflow or vapor-phase reflow).

Nonhalogenated water soluble fluxes (i.e., 0% chloride),

not rosin based fluxes, are recommended for use with

Versatile Link components.

Versatile Link components are moisture sensitive de-

vices and are shipped in a moisture sealed bag. If the

components are exposed to air for an extended period

of time, they may require a baking step before the solder-

ing process. Refer to the special labeling on the shipping

tube for details.

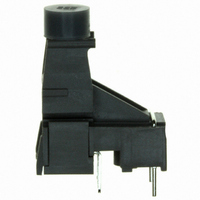

Mechanical Dimensions

Horizontal Modules

(0.109)

3

(0.025)

(0.080)

0.64

2.8

2.0

(0.300)

7.62

1. Shelf life in sealed bag: 1 months at < 40°C and < 90% Relative Humidity (RH).

. After this bag is opened, devices that will be subjected to wave soldering, or

3. Devices require baking, before mounting, if:

4. If baking is required, devices may be baked outside of tube for 0 hours at 75°C.

Bag Seal Date: ______________________________________________________

Note: LEVEL defined by EIA JEDEC Standard J-STD-00

equivalent processing (solder temperature < 60°C for 10 sec) must be:

a) Mounted within 7 hours at factory conditions of ≤ 30°C/60% RH.

b) Stored at ≤ 0% RH.

a) Desiccant changes to PINK.

b) If a or b are not met.

(0.770)

19.6

MOISTURE-SENSITIVE

(0.073)

This bag contains

1.85

3.81 (0.150) MAX.

0.64 (0.025) DIA.

3.56 (0.140) MIN.

CAUTION

(If blank, see barcode label)

DEVICES

(0.270)

6.8

(0.30)

7.6

(0.020)

0.51

Level

4

(0.400)

10.2

(0.200)

(0.100)

5.1

2.5

(0.050)

1.27

(0.165)

4.2

Recommended Chemicals for Cleaning/Degreasing

Alcohols: methyl, isopropyl, isobutyl. Aliphatics: hexane,

heptane. Other: soap solution, naphtha.

Do not use partially halogenated hydrocarbons such

as 1,1.1 trichloroethane, ketones such as MEK, acetone,

chloroform, ethyl acetate, methylene dichloride, phe-

nol, methylene chloride, or N-methylpyrolldone. Also,

Avago does not recommend the use of cleaners that use

halogenated hydrocarbons because of their potential

environmental harm.

Vertical Modules