2154235-1 TE Connectivity, 2154235-1 Datasheet - Page 3

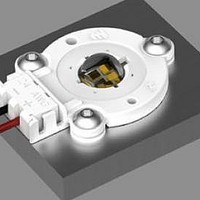

2154235-1

Manufacturer Part Number

2154235-1

Description

Lighting Connectors LED SKT W/O OPT LTCH 40 VDC 1500MA

Manufacturer

TE Connectivity

Type

Wire to Boardr

Specifications of 2154235-1

Product

Socket Connectors

Mounting Style

SMD/SMT

Termination Style

IDC

Contact Plating

Gold

Contact Material

Copper Alloy

Housing Material

Thermoplastic

Current Rating

1.5 A

Voltage Rating

40 VDC

Product Type

Socket

Product Series

LS

Operating Voltage (vdc)

40

Current, Maximum (ma)

1500

Socket Type

LED to Wire

Optics Latch

Without

Contact Base Material

Copper Alloy

Contact Plating, Mating Area, Material

Gold

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Application

Termination for Philips Lumileds LUXEON S LED Application

Lead Free Status / Rohs Status

Details

Mechanical shock.

Durability.

Optic mating force.

Optic unmating force.

Wire termination force.

Termination tensile strength,

parallel.

Termination tensile strength,

perpendicular.

Thermal shock.

Humidity/temperature cycling.

Rev O5

Test Description

No discontinuities of 1 microsecond

or longer duration.

See Note.

See Note.

20.0 N maximum.

10.0 N minimum.

236.2 N maximum.

68.06 N minimum.

16.9 N minimum.

See Note.

See Note.

Figure 1 (continued)

ENVIRONMENTAL

Requirement

EIA-364-27, Method H.

Subject mated specimens to 30 G's

half-sine shock pulses of 11

milliseconds duration. Three shocks

in each direction applied along 3

mutually perpendicular planes, 18

total shocks.

See Figure 4.

EIA-364-9.

Mount and unmount specimens for

5 cycles at a maximum rate of 500

cycles per hour.

EIA-364-13.

Measure force necessary to mate

specimens at a maximum rate of

12.7 mm per minute.

EIA-364-13.

Measure force necessary to unmate

specimens at a maximum rate of

12.7 mm per minute.

EIA-364-13.

Measure force necessary to seat 2

wires into the IDC contacts at a

maximum rate of 12.7 mm per

minute.

EIA-364-8.

Determine tensile strength by

pulling parallel to terminated wire

at a maximum rate of 25.4 mm per

minute.

See Figure 5.

EIA-364-8.

Determine tensile strength by

pulling perpendicular to terminated

wire at a maximum rate of 25.4 mm

per minute.

See Figure 6.

EIA-364-32, Test Condition VIII.

Subject specimens to 25 cycles

between -40 and 105°C with 30

minute dwells at temperature

extremes and 1 minute transition

between temperatures.

EIA-364-31, Method III.

Subject specimens to 10 cycles (10

days) between 25 and 65°C at 80 to

100% RH.

Procedure

108-2455

3 of 8