LMZ23605TZ National Semiconductor, LMZ23605TZ Datasheet - Page 17

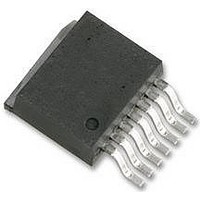

LMZ23605TZ

Manufacturer Part Number

LMZ23605TZ

Description

POWER MODULE, 36V, 5A, 7TO-PMOD

Manufacturer

National Semiconductor

Datasheet

1.LMZ23605TZ.pdf

(22 pages)

Specifications of LMZ23605TZ

Primary Input Voltage

36V

No. Of Outputs

1

Output Voltage

6V

Output Current

5A

Voltage Regulator Case Style

TO-PMOD

No. Of Pins

7

Operating Temperature Range

-40°C To +125°C

Rohs Compliant

Yes

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

PC BOARD LAYOUT GUIDELINES

PC board layout is an important part of DC-DC converter de-

sign. Poor board layout can disrupt the performance of a DC-

DC converter and surrounding circuitry by contributing to EMI,

ground bounce and resistive voltage drop in the traces. These

can send erroneous signals to the DC-DC converter resulting

in poor regulation or instability. Good layout can be imple-

mented by following a few simple design rules. A good ex-

ample layout is shown in Figure 5.

1. Minimize area of switched current loops.

From an EMI reduction standpoint, it is imperative to minimize

the high di/dt paths during PC board layout as shown in the

figure above. The high current loops that do not overlap have

high di/dt content that will cause observable high frequency

noise on the output pin if the input capacitor (Cin1) is placed

at a distance away from the LMZ23605. Therefore place

C

exposed pad. This will minimize the high di/dt area and reduce

radiated EMI. Additionally, grounding for both the input and

output capacitor should consist of a localized top side plane

that connects to the PGND exposed pad (EP).

2. Have a single point ground.

The ground connections for the feedback, soft-start, and en-

able components should be routed to the AGND pin of the

device. This prevents any switched or load currents from

flowing in the analog ground traces. If not properly handled,

poor grounding can result in degraded load regulation or er-

ratic output voltage ripple behavior. Additionally provide the

single point ground connection from pin 4 (AGND) to EP/

PGND.

3. Minimize trace length to the FB pin.

Both feedback resistors, R

close to the FB pin. Since the FB node is high impedance,

maintain the copper area as small as possible. The traces

from R

LMZ23605 to minimize possible noise pickup.

4. Make input and output bus connections as wide as

possible.

This reduces any voltage drops on the input or output of the

converter and maximizes efficiency. To optimize voltage ac-

curacy at the load, ensure that a separate feedback voltage

sense trace is made to the load. Doing so will correct for volt-

age drops and provide optimum output accuracy.

5. Provide adequate device heat-sinking.

Use an array of heat-sinking vias to connect the exposed pad

to the ground plane on the bottom PCB layer. If the PCB has

a plurality of copper layers, these thermal vias can also be

employed to make connection to inner layer heat-spreading

IN1

as close as possible to the LMZ23605 VIN and PGND

FBT

, R

FBB

should be routed away from the body of the

FIGURE 3.

FBT

and R

FBB

should be located

30116911

17

ground planes. For best results use a 6 x 10 via array with

minimum via diameter of 10mils (254 μm) thermal vias spaced

39mils (1.0 mm). Ensure enough copper area is used for heat-

sinking to keep the junction temperature below 125°C.

Additional Features

SYNCHRONIZATION INPUT

The PWM switching frequency can be synchronized to an ex-

ternal frequency source. If this feature is not used, connect

this input either directly to ground, or connect to ground

through a resistor of 1.5 kΩ ohm or less. The allowed syn-

chronization frequency range is 650kHz to 950 kHz. The

typical input threshold is 1.4V transition level. Ideally the input

clock should overdrive the threshold by a factor of 2, so direct

drive from 3.3V logic via a 1.5kΩ Thevenin source resistance

is recommended. Note that applying a sustained “logic 1” cor-

responds to zero hertz PWM frequency and will cause the

module to stop switching.

OUTPUT OVER-VOLTAGE PROTECTION

If the voltage at FB is greater than a 0.86V internal reference,

the output of the error amplifier is pulled toward ground, caus-

ing V

CURRENT LIMIT

The LMZ23605 is protected by both low side (LS) and high

side (HS) current limit circuitry. The LS current limit detection

is carried out during the off-time by monitoring the current

through the LS synchronous MOSFET. Referring to the Func-

tional Block Diagram, when the top MOSFET is turned off, the

inductor current flows through the load, the PGND pin and the

internal synchronous MOSFET. If this current exceeds 5.4A

(typical) the current limit comparator disables the start of the

next switching period. Switching cycles are prohibited until

current drops below the limit. It should also be noted that d.c.

current limit is dependent on both duty cycle as illustrated in

the graph in the typical performance section. The HS current

limit monitors the current of top side MOSFET. Once HS cur-

rent limit is detected (7A typical) , the HS MOSFET is shut off

immediately, until the next cycle. Exceeding HS current limit

causes V

limit is that f

THERMAL PROTECTION

The junction temperature of the LMZ23605 should not be al-

lowed to exceed its maximum ratings. Thermal protection is

implemented by an internal Thermal Shutdown circuit which

activates at 165 °C (typ) causing the device to enter a low

power standby state. In this state the main MOSFET remains

off causing V

discharged to ground. Thermal protection helps prevent

catastrophic failures for accidental device overheating. When

the junction temperature falls back below 150 °C (typ Hyst =

15°C) the SS pin is released, V

operation resumes.

Applications requiring maximum output current especially

those at high input voltage may require additional derating at

elevated temperatures.

PRE-BIASED STARTUP

The LMZ23605 will properly start up into a pre-biased output.

This startup situation is common in multiple rail logic applica-

tions where current paths may exist between different power

rails during the startup sequence. The following scope cap-

ture shows proper behavior in this mode. Trace one is Enable

O

to fall.

O

to fall. Typical behavior of exceeding LS current

SW

O

drops to 1/2 of the operating frequency.

to fall, and additionally the C

O

rises smoothly, and normal

SS

www.national.com

capacitor is