5532823-2 TE Connectivity, 5532823-2 Datasheet - Page 3

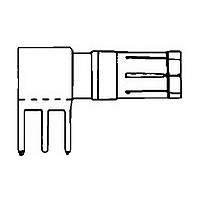

5532823-2

Manufacturer Part Number

5532823-2

Description

CONTACT, RECEPTACLE, POWER, RIGHT ANGLE,

Manufacturer

TE Connectivity

Specifications of 5532823-2

Product Type

Contact

Pcb Mounting Orientation

Right Angle

Pcb Mount Retention

Without

Solder Tail Contact Plating

Tin

Contact Type

Socket

Contact Plating, Mating Area, Material

Gold (30)

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Wave solder capable to 240°C, Wave solder capable to 260°C, Wave solder capable to 265°C, Reflow solder capable to 245°C, Reflow solder capable to 260°C, Pin-in-Paste capable to 245°C, Pin-in-Paste capable to 260°C

Rohs/elv Compliance History

Always was RoHS compliant

Application

Board-to-Board Power

Unm ating force.

Contact retention.

Contact engaging force.

Contact separating force.

Durability.

Resistance to soldering heat.

Insertion force, ACTION PIN.

Retention force, ACTION PIN.

Torque, ACTION PIN.

Therm al shock.

Hum idity-tem perature cycling.

Rev C

Test Description

No physical dam age.

40 pounds m axim um per pin.

Pin shall not dislodge from printed

.4 ounces m inim um average per

contact.

Contacts shall not dislodge from its

norm al locking position.

4 ounces m axim um per contact.

.1 ounce m inim um .

No physical dam age.

.020 ohm s m axim um term ination

resistance, low level.

Contact separation force.

wiring board.

Pin shall not m ove or dislodge from

printed wiring board.

.020 ohm s m axim um term ination

resistance, low level.

1000 m egohm s final insulation

resistance.

ENVIRONMENTAL

Figure 1 (end)

Requirem ent

Measure force to engage using

Size 3 tim es using gage 2, insert

Subject term inal posts m ounted on

Fully insert pin into printed wiring

Measure force necessary to unm ate

connector assem bly.

Calculate force per contact.

TE Spec 109-42, Condition A.

Apply axial load of 3 pounds to

individual contacts.

TE Spec 109-30.

gage 2.

See Figure 4.

TE Spec 109-35.

gage 1 and m easure force to

separate.

See Figure 4.

TE Spec 109-35.

Mate and unm ate pin and

receptacle connectors for 250

cycles.

TE Spec 109-27.

printed circuit boards to solder bath

at 260 ±5 C for 10 ±2 seconds.

Spec 109-63-3.

board hole.

Apply an axial load of 10 pounds for

10 seconds.

Apply 2 inch ounces for 10 seconds

in both directions.

Subject m ated connectors to 5

cycles between -65 and 125°C.

TE Spec 109-22.

Subject m ated connectors to 10

hum idity-tem perature cycles

between 25 and 65°C at 95% RH.

TE Spec 109-23, Method III,

Condition B, less steps 7 a and 7b.

Procedure

108-9063

3 of 6