32837-1 TE Connectivity, 32837-1 Datasheet - Page 27

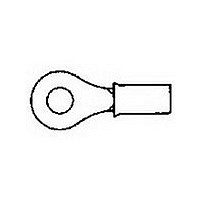

32837-1

Manufacturer Part Number

32837-1

Description

TERMINAL,PIDG R 22-16 10

Manufacturer

TE Connectivity

Type

Ring Tongue Terminalr

Datasheet

1.32837-1.pdf

(30 pages)

Specifications of 32837-1

Stud Size

5mm

Color

Red

Wire Gauge

16-22

Body Plating

Tin

Body Material

Copper

Insulation

Nylon

Product Depth (mm)

8.74mm

Product Length (mm)

22.25mm

Rohs Compliant

YES

Terminal Shape

Ring Tongue

Receptacle Style

Straight

Body Style

PIDG

Barrel Type

Closed Barrel

Wire/cable Type

Regular Wire

Insulation Support

Insulation Support

Insulation Diameter (mm [in])

3.56 [.140] Max.

Stud Diameter (mm [in])

4.82 [0.190]

Shape

RING-041

Heavy Duty

No

Finish

Tin

Insulation Material

Nylon

Voltage (vac)

300

Wire/cable Size (cma)

509 – 3,260

Wire Range (mm [awg])

0.30-1.40² [22-16]

Tongue Material Thickness (mm [in])

0.84 [0.033]

Government/industry Qualification

No

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Tape Mounted

Lead Free Status / Rohs Status

Compliant

Product Facts

The AMP Mated

Tool/Terminal Concept

The Crimp

Dimensions are shown for reference

purposes only.

Pre-insulated terminal

designed for uniformed

reliability in most difficult

circuit environment

Consists of an unplated or

tin-plated brass body or a

tin-plated phosphor bronze

body with a specially

designed copper sleeve

and insulation sleeve fitted

over the terminal barrel

Design of the tool dies and

construction of the terminal

permits uniform insulation

thickness under crimping

pressure, transmitting this

pressure evenly to the cen-

ter of the crimp area

AMP compression crimping

produces crimps for a given

size wire and terminal that

are alike in appearance and

p e r f o r m a n c e

Terminal and the crimping

tool are designed as uni -

form matched devices

Dies are precision-

engineered from the finest

hard-metal alloys

Crimping pressure is con-

trolled by a ratchet device on

the hand tool or a correspond-

ing pre-calibration in the

crimping jaws of AMP auto -

mated crimping machines

When done properly,

crimping pressure can nei-

ther overstress nor under-

stress the terminal barrel —

machined dies fully bottom

to the precise crimp height

Resulting termination is

free of contamination

Resistant to shock and criti-

cal environments

Tensile strength approaches

that of the wire itself

Standard Terminals and Splices

PIDG FASTON

Table of Contents

Terminals

Splices

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets are

metric equivalents.

Temperature Rating: 105°C Max.

1

Copper Sleeve. The specially

designed copper sleeve,

fitted over the terminal barrel,

provides circumferential

insulation support to the

wire and allows the wire to

be bent in any direction,

without fraying the wire’s

insulation or breaking

the conductor.

Funnel Ramp Entry.

Prevents a turned back strand and

rapid wire insertion during high

speed production.

UL& CSA— Nylon except where noted

Receptacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35

Receptacles (Insulation Restricting) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Line Splice Connector for “250” Series and “187” Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Range

22-18

16-14

12-10

AMP

Wire

Color Coding. Terminal insulation is

color-coded by wire range to prevent

errors during installation.

(Use Type TETRA-CRIMP*Tooling)

AMP PIDG FASTON Terminals

22-18 Stranded

16-14 Stranded

12-10 Stranded

Component

Recognized

File E 66717

Nylon Insulation. Nylon

sleeve has high dielectric

strength.

300 V Max., 105°C. Max.

Specifications subject to change.

Certified

LR 7189

Serrations. Serrations inside

barrel provide maximum contact

and tensile strength after crimping.

1

AMPPart No.

1-321235-0

1-321235-1

321235

321688

Component

Recognized

File E 66717 (Vinyl)

Line Splice Connectors

Basic Terminal Material. The basic terminal

is constructed of fine grade high conductivity

brass per ASTM B-36 or phosphor bronze

per ASTM B-139. The brass terminal is either

unplated or tin-plated per ASTM B-545.

The phosphor bronze terminal is tin-plated per

ASTM B-545. AMP’s special plating process

creates durable corrosion resistance to salt

spray and most chemical fumes.

AMP PIDG FASTON

“250” Series

Technical Support Center

1-800-522-6752

www.amp.com

105°C

600 V

300 V

Max.

Max.

Max.

AMPPart No.

1-321235-0

1-321235-1

321235

321688

LR 7189

Certified

Catalog 82042

Revised 8-00

(Vinyl)

105°C

300 V

300 V

Max.

Max.

Max.

33