171661-2 TE Connectivity, 171661-2 Datasheet - Page 4

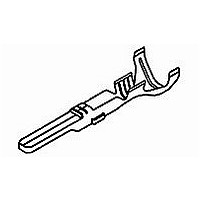

171661-2

Manufacturer Part Number

171661-2

Description

E-J MK-2 070 TAB CONT

Manufacturer

TE Connectivity

Series

070r

Specifications of 171661-2

Rohs Compliant

YES

Product Line

Econoseal J

Product Type

Contact

Wire/cable Type

Discrete Wire

Cable Type

Thin Wall

Termination Method To Wire/cable

Crimp

Wire/cable Size (awg)

16 – 20

Wire/cable Size (mm²)

0.5 – 1.25

Wire Type

Stranded

Contact Type

Tab

Contact Base Material

Brass

Contact Plating, Mating Area, Material

Select Gold

Contact Plating, Mating Area, Thickness (µm [?in])

0.76 [29.92]

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Applies To

Wire/Cable

Accepts Wire Insulation Diameter, Range (mm [in])

2.00 – 2.60 [0.079 – 0.102]

Application Use

Wire-to-Wire

Contact Transmits (typical Application)

Power

Packaging Method

Reel

Packaging Quantity

6000

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

171661-2

Manufacturer:

TE

Quantity:

144 000

Rev B

High temperature exposure.

Humidity-temperature cycling.

Immersion.

Pressure/vacuum leak.

NOTE

Test Description

Shall meet visual requirements, show no physical damage, and meet requirements of additional

tests as specified in the Product Qualification and Requalification Test Sequence shown in Figure

2.

See Note.

See Note.

No evidence of leakage.

See Note.

No evidence of leakage.

See Note.

Figure 1 (end)

Requirement

USCAR 5.6.3. (Rev 4/01)

Subject mated specimens to

temperature life at 125° C for PBT

housings and 150° C for nylon

housings for 1008 hours.

USCAR 5.6.2. (Rev 4/01)

Subject mated specimens to 15

specified cycles.

See Figure 8.

USCAR 5.3.15. (Rev 8/97)

Subject mated specimens to the

following procedure:

1. Temperature soak specimens for

2 hours at 125° C for PBT housings

and 150° C for nylon housings.

2. Remove specimens from oven

and immediately immerse in 25° C

5% salt solution for 2 hours.

Measure dry circuit resistance.

3. Repeat procedure 4 more times.

USCAR 5.3.16. (Rev 8/97)

Subject mated specimens to the

following procedure:

1. Immerse specimens in 25° C 5%

salt solution and slowly pressurize

to 48 kpa while observing for air

bubbles.

2. Remove pressure and slowly

apply 48 kpa of vacuum.

3. Unmate specimens and examine

for leakage.

4. Temperature soak specimens for

72 hours at 125° C for PBT

housings and 150° C for nylon

housings.

5. Remove specimens and repeat

steps 1 and 2 using 28 kpa.

Procedure

108-1790

4 of 9