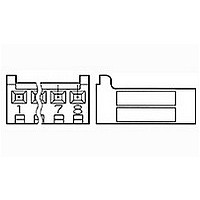

1-770602-8 TE Connectivity, 1-770602-8 Datasheet

1-770602-8

Specifications of 1-770602-8

Available stocks

Related parts for 1-770602-8

1-770602-8 Summary of contents

Page 1

... AWG wire. 1.2. Qualification When tests are performed on the subject product line, procedures specified in Figure 1 shall be used. All inspections shall be performed using the applicable inspection plan and product drawing. 1.3. Successful qualification testing on the subject product line was completed on 18Apr96. The Qualification Test Report number for this testing is 501-341 ...

Page 2

... Temperature: -55 to 105° C 3.4. Performance and Test Description Product is designed to meet the electrical, mechanical and environmental performance requirements specified in Figure 1. Unless otherwise specified, all tests shall be performed at ambient environmental conditions per Test Specification 109-1. 3.5. Test Requirements and Procedures Summary Test Description Examination of product ...

Page 3

... Shall meet visual requirements, show no physical damage and shall meet requirements of NOTE additional tests as specified in Test Sequence in Figure 2. Rev C Requirement No discontinuities of 1 microsecond or longer duration. See Note. See Note. Two pounds maximum per contact. TE Spec 109-42, Condition A. .80 pound minimum per contact. Wire Size Crimp Tensile (AWG) (Lbs minimum ...

Page 4

... Unmating force Crimp tensile Thermal shock Humidity/temperature cycling Temperature life Mixed flowing gas (a) See paragraph 4.1.A. NOTE (b) Numbers indicate sequence in which tests are performed. (c) Discontinuities shall not be measured. Energize at 18 Test Specification 109-151. (d) Precondition specimens with 10 cycles durability. Rev C Test Group ( ...

Page 5

... CST-100 contact to header: 30 µ µin Au; 30 µ µin PdNi; 30 µin PdNi to 30 µin Au; 30 µin PdNi to 30 µin PdNi; 15 µ µin Au; 15 µ µin PdNi; 15 µin PdNi to 15 µin Au; and 15 µin PdNi to 15 µin PdNi. ...

Page 6

... Rev C Figure 3 Termination Resistance Measurement Points 108-1328 ...

Page 7

... Multiplication Factor (F) from the above chart and multiply it times the Base rated Current for a single circuit at maximum ambient operating temperature as shown in Figure 4A. Rev C Figure 4A Current Carrying Capability Wire Size AWG 26 Single Contact 0.74638 0.85868 50 0.50479 0.58073 0.67631 100 0.42088 0.48421 0.56390 Figure 4B Current Rating 108-1328 ...

Page 8

... Rev C Figure 5 Vibration & Physical Shock Mounting Fixture 108-1328 ...