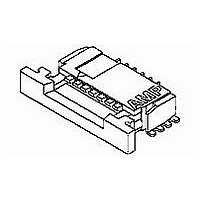

1-487951-8 TE Connectivity, 1-487951-8 Datasheet

1-487951-8

Specifications of 1-487951-8

Related parts for 1-487951-8

1-487951-8 Summary of contents

Page 1

... Content This specification covers performance, tests and quality requirements for the FPC connector. This connector ranges in size from positions. A single contact is produced with tails to provide right angle surface mount connections to a printed circuit board. An actuator provides ZIF action and the socket accepts FEC, FFC, or FPC ...

Page 2

... Performance and Test Description Product is designed to meet the electrical, mechanical and environmental performance requirements specified in Figure 1. Unless otherwise specified, all tests shall be performed at ambient environmental conditions per Test Specification 109-1. 3.5. Test Requirements and Procedures Summary Test Description Examination of product. ...

Page 3

... Figure 2 108-1393 Procedure TE Spec 109-30. Apply axial load off 100 grams to contacts in vertical direction and hold for 30 seconds minimum. TE Spec 109-22. Subject mated samples to 5 cycles between -40 and 85° Spec 109-23-3, Condition B. Subject mated samples to 10 cycles between 25 and 65° 95% RH. Final measurements shall be taken during recovery period ...

Page 4

... Samples shall be prepared in accordance with applicable Instruction Sheets and shall be selected at random from current production. All test groups shall consist of a minimum of 5 connectors. Test groups 1 and 2 shall be soldered to printed circuit boards. A minimum of 30 contacts from these test groups shall be randomly selected and tested. If available, test group 1 shall contain both minimum and maximum size connectors ...

Page 5

... Rev C Figure 3 Termination Resistance Measurement Points 108-1393 ...

Page 6

... Vibration & Mechanical Shock Mounting Fixture Rev C Figure 4 108-1393 ...