103308-2 TE Connectivity, 103308-2 Datasheet - Page 117

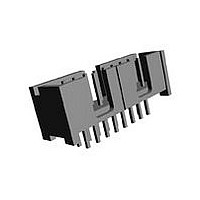

103308-2

Manufacturer Part Number

103308-2

Description

Conn Shrouded Header HDR 14 POS 2.54mm Solder ST Thru-Hole

Manufacturer

TE Connectivity

Type

Shrouded Headerr

Specifications of 103308-2

Pitch

2.54 mm

Number Of Rows

2

Number Of Contacts

14

Gender

HDR

Contact Plating

Gold Over Nickel/Gold Over Palladium Nickel

Termination Method

Solder

Pitch (mm)

2.54mm

Number Of Contact Rows

2

Mounting Style

Through Hole

Body Orientation

Straight

Operating Temp Range

-65C to 105C

Current Rating (max)

1/ContactA

Contact Material

Copper Alloy

Housing Material

Thermoplastic

Housing Color

Black

Product Height (mm)

9.77mm

Product Length (mm)

25.4mm

Product Depth (mm)

9.14mm

Rohs Compliant

NO

Product Line

AMP-LATCH

Profile

Low

Pcb Mounting Orientation

Vertical

Pcb Mount Retention

Without

Mating Connector Lock

Without

Housing Style

4-Sided

Ejection Latches

Without

Post Size (mm [in])

0.64 [.025]

Shrouded

Yes

[shrouded] End Dimension (mm [in])

3.81 [0.150]

Current Rating (a)

1

Insulation Resistance (m?)

5,000

Termination Post Length (mm [in])

3.05 [0.120]

Solder Tail Contact Plating

Tin-Lead over Nickel

Header Type

Pin Header

Number Of Positions

14

Centerline, Matrix (mm [in])

2.54 x 2.54 [.100 x .100]

Daisy Chain

With

Preloaded

Yes

Contact Plating, Mating Area, Material

Gold (15), Gold Flash over Palladium Nickel

Contact Shape

Square

Contact Base Material

Copper Alloy

Connector Style

Header - Pin

Mating Alignment Type

Center, Dual Polarizing Bar

Mating Alignment

With

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

ELV compliant, 5 of 6 Compliant

Lead Free Solder Processes

Not suitable for lead free processing

Approved Standards

UL E28476, CSA LR7189

Operating Temperature (°c)

-65 – +105

Temperature Rating

Standard

Lead Free Status / RoHS Status

Not Compliant

5

200

Catalog 1307819

Revised 6-04

www.tycoelectronics.com

Closed Dual Entry, Side and

End Stackable Low Profile,

.100 x .100 [2.54 x 2.54]

Centerline, .150 [3.81] Tine

S p a c i n g

Photo 110925

Material and Finish:

Housing—Black thermoplastic,

94V-0 rated

Contacts—Phosphor bronze,

plated as follows:

Plating A—Duplex .000030 [0.00076]

gold on contact area, .000150-.000300

[0.00381-0.00762] tin-lead on solder

area all over .000050 [0.00127] nickel

Plating B—Duplex .000010

[0.000254] gold on contact area,

.000150-.000300 [0.00381-0.00762]

tin-lead on solder area all over .000050

[0.00127] nickel

Plating C—.000100-.000200

[0.00254-0.00508] tin-lead over

.000050 [0.00127] nickel

Related Product Data:

Mateable Headers—Refer

to the Mating Post Selection Guide

(page 89)

Performance Characteristics—page

191

Technical Documents

Product Specification 108-25022

Application Specification

114-25018

(page 294):

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

[

.075

.060

1.90

AMPMODU Interconnection System

[5.03]

Notes: 1. Tyco Electronics recommends mating gold or duplex plated headers with duplex plated receptacle

Mod. IV Receptacle Assemblies, Double-Row,

.100 x .100 [2.54 x 2.54] Centerline

.198

No. of

P o s .

+.005

+0.13

-.000

- 0.00

[2.54]

1 0

1 2

1 4

1 6

1 8

2 0

2 2

2 4

2 6

2 8

3 0

3 2

3 4

3 6

3 8

4 0

.100

2

4

6

8

]

2. To obtain the minimum mating post length, add .020 [0.51] (not including the post lead in chamfer) to

for Bottom Entry or Pass Through Applications

Typ.

Dia.

assemblies.

the maximum point-of-contact dimension, and .062 [1.57] for recommended board thickness if used in

bottom entry application.

*±.003 [±0.08] tolerances not to accumulate

Recommended PC Board Hole Layout

1 . 0 0 0 [ 2 5 . 4 0 ]

1 . 1 0 0 [ 2 7 . 9 4 ]

1 . 2 0 0 [ 3 0 . 4 8 ]

1 . 3 0 0 [ 3 3 . 0 2 ]

1 . 4 0 0 [ 3 5 . 5 6 ]

1 . 5 0 0 [ 3 8 . 1 0 ]

1 . 6 0 0 [ 4 0 . 6 4 ]

1 . 7 0 0 [ 4 3 . 1 8 ]

1 . 8 0 0 [ 4 5 . 7 2 ]

1 . 9 0 0 [ 4 8 . 2 6 ]

2 . 0 0 0 [ 5 0 . 8 0 ]

.100 [ 2 . 5 4 ]

. 2 0 0 [ 5 . 0 8 ]

. 3 0 0 [ 7 . 6 2 ]

. 4 0 0 [ 1 0 . 1 6 ]

. 5 0 0 [ 1 2 . 7 0 ]

. 6 0 0 [ 1 5 . 2 4 ]

. 7 0 0 [ 1 7 . 7 8 ]

. 8 0 0 [ 2 0 . 3 2 ]

. 9 0 0 [ 2 2 . 8 6 ]

[1.27]

Max.

.050

Typ.

within one connector pattern.

A

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

D i m e n s i o n s

[2.54]

B

A

.100

Typ.

1 . 0 0 0 [ 2 5 . 4 0 ]

1 . 1 0 0 [ 2 7 . 9 4 ]

1 . 2 0 0 [ 3 0 . 4 8 ]

1 . 3 0 0 [ 3 3 . 0 2 ]

1 . 4 0 0 [ 3 5 . 5 6 ]

1 . 5 0 0 [ 3 8 . 1 0 ]

1 . 6 0 0 [ 4 0 . 6 4 ]

1 . 7 0 0 [ 4 3 . 1 8 ]

1 . 8 0 0 [ 4 5 . 7 2 ]

1 . 9 0 0 [ 4 8 . 2 6 ]

. 1 0 0 [ 2 . 5 4 ]

.200 [ 5 . 0 8 ]

. 3 0 0 [ 7 . 6 2 ]

. 4 0 0 [ 1 0 . 1 6 ]

. 5 0 0 [ 1 2 . 7 0 ]

. 6 0 0 [ 1 5 . 2 4 ]

. 7 0 0 [ 1 7 . 7 8 ]

. 8 0 0 [ 2 0 . 3 2 ]

. 9 0 0 [ 2 2 . 8 6 ]

B

—

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

[6.22]

.245

Typ.

(Standoffs)

[2.54±0.08]

.100±.003

[0.51]

.020

Typ.

[2.54]

.100

Typ.

1 - 5 3 5 5 4 2 - 0

1 - 5 3 5 5 4 2 - 1

1 - 5 3 5 5 4 2 - 2

1 - 5 3 5 5 4 2 - 3

1 - 5 3 5 5 4 2 - 4

1 - 5 3 5 5 4 2 - 5

1 - 5 3 5 5 4 2 - 6

1 - 5 3 5 5 4 2 - 7

1 - 5 3 5 5 4 2 - 8

1 - 5 3 5 5 4 2 - 9

2 - 5 3 5 5 4 2 - 0

[0.89±0.08]

Plating A

.035±.003

5 3 5 5 4 2 - 1

5 3 5 5 4 2 - 2

5 3 5 5 4 2 - 3

5 3 5 5 4 2 - 4

5 3 5 5 4 2 - 5

5 3 5 5 4 2 - 6

5 3 5 5 4 2 - 7

5 3 5 5 4 2 - 8

5 3 5 5 4 2 - 9

(Localized Gold

Plate Area)

Recommended PC Board Hole Layout

[3.77]

[2.72]

.107

Typ.

.148

Typ.

Dia. Typ.

Contact Plating/Part Nos.

[2.54]

.100

Typ.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

1 - 1 4 7 0 9 5 - 0

1 - 1 4 7 0 9 5 - 1

1 - 1 4 7 0 9 5 - 2

1 - 1 4 7 0 9 5 - 3

1 - 1 4 7 0 9 5 - 4

1 - 1 4 7 0 9 5 - 5

1 - 1 4 7 0 9 5 - 6

1 - 1 4 7 0 9 5 - 7

1 - 1 4 7 0 9 5 - 8

1 - 1 4 7 0 9 5 - 9

2 - 1 4 7 0 9 5 - 0

for Top Entry

Plating B

1 4 7 0 9 5 - 1

1 4 7 0 9 5 - 2

1 4 7 0 9 5 - 3

1 4 7 0 9 5 - 4

1 4 7 0 9 5 - 5

1 4 7 0 9 5 - 6

1 4 7 0 9 5 - 7

1 4 7 0 9 5 - 8

1 4 7 0 9 5 - 9

Point of

Contact

B

[3.30±0.25]

1 - 1 4 7 0 9 6 - 0

1 - 1 4 7 0 9 6 - 1

1 - 1 4 7 0 9 6 - 2

1 - 1 4 7 0 9 6 - 3

1 - 1 4 7 0 9 6 - 4

1 - 1 4 7 0 9 6 - 5

1 - 1 4 7 0 9 6 - 6

1 - 1 4 7 0 9 6 - 7

1 - 1 4 7 0 9 6 - 8

1 - 1 4 7 0 9 6 - 9

2 - 1 4 7 0 9 6 - 0

.130±.010

Plating C

1 4 7 0 9 6 - 1

1 4 7 0 9 6 - 2

1 4 7 0 9 6 - 3

1 4 7 0 9 6 - 4

1 4 7 0 9 6 - 5

1 4 7 0 9 6 - 6

1 4 7 0 9 6 - 7

1 4 7 0 9 6 - 8

1 4 7 0 9 6 - 9

[3.81]

.150

Typ.

Typ.

[3.81]

.150

Typ.