1445904-1 TE Connectivity, 1445904-1 Datasheet - Page 29

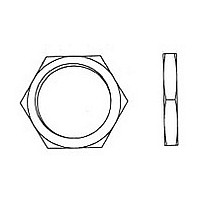

1445904-1

Manufacturer Part Number

1445904-1

Description

Connector Accessories Jam Nut Brass

Manufacturer

TE Connectivity

Type

Nutr

Specifications of 1445904-1

Product Depth (mm)

3.18mm

Product Height (mm)

22.25mm

Accessory Type

Jam Nut

Width

0.875"

Height

0.125"

Leaded Process Compatible

Yes

Thread Size - Imperial

3/4-20 UNEF-2B

Rohs Compliant

Yes

Nut Size

3⁄4-20

Nut Type

Jam Nut

Standards

RoHS, ELV Compliants

Current Carrying Capacity

5 Amps

Operating Voltage

600 VAC Minimum

Dielectric Withstanding Voltage

2200 VAC Minimum Mechanical Specification

Seal, Wire Entry

Elastomer, Yellow

Seal, Peripheral

Elastomer, Gray

Housing

Thermoplastic, Black

Ring, Coupling

Thermoplastic, Black

Plate, Seal Retention

Thermoplastic, Black

Product Type

Accessory

Shell Size

11

Thread Size

3/4-20

Jam Nut Plating

Nickel

Jam Nut Material

Brass

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not reviewed for lead free solder process

Rohs/elv Compliance History

Always was RoHS compliant

Lead Free Status / RoHS Status

Compliant

For Use With

Micro Circular Plastic Connectors

Lead Free Status / Rohs Status

RoHS Compliant part

80

Crimp Machines

AMP-O-LECTRIC Model “G”

Terminating Machines,

Part Nos. 354500-1, -9, -11

Crimp Quality Monitor (CQM)

Part No. 1320420-2

System III Applicator

Catalog 82021

Revised 7-07

www.tycoelectronics.com

For more information, request Catalog

1654956-8

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

AMP Circular Connectors for

Commercial Signal and Power Applications

Application Tooling

Semiautomatic bench

machines for crimping

reeled terminals and con-

tacts, featuring a quiet and

reliable direct motor drive,

microprocessor controls for

ease of setup and opera-

tion, and guarding and

lighting designed for opera-

tor convenience and safety.

All models are equipped

with either manual or auto-

matic precision adjustment

of crimp height. Machine-

mounted sensors are avail-

able for crimp quality moni-

toring using conventional

miniature-style applicators.

For more information, request

Catalog 1654956-2, Video 198116,

Catalog 82275 [Crimp Quality

Monitor (CQM)], Video 198094.

Note: New Stripping Module

available, see page 79.

The unique system provides

100% on-the-fly crimp

inspection. It measures the

crimp height of each

termination, and evaluates

the quality of each crimp. If

a crimp is questionable, the

monitor alerts the operator

with both visual and audible

alarms. It also provides

ports for printing and

networking. When used with

AMP-O-LECTRIC Model “G”

Termination Machines, the

monitor is mounted to the

machine. When used with

AMPOMATOR CLS IV Lead

Making Machines, it is

integrated into the

machine’s operating

system.

For more information, request

Catalog 82275.

The System III Applicator

introduces several new

technologies into the

applicator including a

precision servo-electric

motorized feeding system,

a built-in data module for

storing terminal crimp and

set-up information, a

precision fit round ram, and

a newly designed terminal

depressor. It still utilizes the

proven quality of the HD-M

crimper and anvil tooling.

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

(Continued)

AMP-TAPETRONIC Machine,

Part No. 69875

AMP 3K/40 and AMP 5K/40

Terminating Machines

The AMP 3K/40 and AMP

5K/40 Terminators are

designed for customers that

require the increased

output and quality of a

semiautomatic machine at

a competitive price. By

incorporating the most

commonly requested

features as standard and

offering a long list of

optional equipment, these

terminators offer flexibility to

meet the specific needs of

various applications at the

lowest possible cost.

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 52-55-1106-0800

C. America: 57-1-254-4444

Note:

are RoHS Compliant.

All part numbers

AMP-O-LECTRIC Model “K”

Terminating Machine with a

permanently-mounted

applicator that accepts

interchangeable die sets to

apply a variety of tape-

mounted terminals and

splices. Many of the die

sets can also be used in

AMP-O-LECTRIC

Terminating Machines with

a tape applicator.

For more information, contact Tyco

Electronics.

I

I

I

I

I

I

For more information, request

Catalog 1654956-2.

Note: New Stripping Module

available, see page 79.

3,000 lb [1361 kg] max.

crimp force (AMP 3K/40);

5,000 lb [2268 kg] max.

crimp force (AMP 5K/40)

Toolless removal of

applicators and guards

Jog capability

Quiet, fast operation —

80/76 dBA and cycle time

less than 0.400 seconds

Accepts Heavy Duty Mini

stye applicators

Wide range of optional

equipment such as toolless

precision crimp height

adjust, batch counter, CQM

capability and work light

South America: 55-11-2103-6000

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-208-420-8341