PR03000206802JAC00 Vishay, PR03000206802JAC00 Datasheet - Page 14

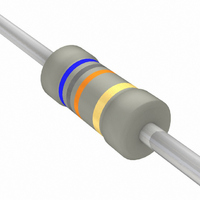

PR03000206802JAC00

Manufacturer Part Number

PR03000206802JAC00

Description

Res Metal Film 68K Ohm 5% 3W ±250ppm/°C Conformal AXL Thru-Hole Ammo Pack

Manufacturer

Vishay

Type

Metal Filmr

Series

PR03r

Specifications of PR03000206802JAC00

Resistance Value

68 KOhm

Power Rating

3 W

Tolerance

5 %

Resistance

68 KOhms

Voltage Rating

750 Volts

Temperature Coefficient

±250ppm/°C

Resistance (ohms)

68K

Power (watts)

3W

Composition

Metal Film

Features

Flame Retardant Coating

Size / Dimension

0.205" Dia x 0.768" L (5.20mm x 19.50mm)

Lead Style

Through Hole

Package / Case

Axial

Resistance In Ohms

68.0K

Case

Axial

Termination Style

Axial

Operating Temperature Range

- 55 C to + 155 C

Dimensions

5.2 mm Dia. x 16.7 mm L

Resistance Tolerance

± 5%

Resistor Element Material

Metal Film

Power Rating(s)

3W

Tolerance (+ Or -)

5%

Operating Temp Range

-55C to 155C

Case Style

Conformal

Failure Rate

Not Required

Lead Spacing (nom)

Not Requiredmm

Product Length (mm)

19.5mm

Product Depth (mm)

Not Requiredmm

Product Height (mm)

Not Requiredmm

Construction

Cylindrical

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Height

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

2322 195 14683

232219514683

5093NW68K00JBC

BC68KW-3JTB

232219514683

5093NW68K00JBC

BC68KW-3JTB

Document Number: 28729

Revision: 14-Oct-09

CLAUSE

TEST PROCEDURES AND REQUIREMENTS

4.17

4.7

4.16

4.16.2

4.16.3

4.16.4

4.20

4.22

4.19

4.23

4.23.2

4.23.3

4.23.4

4.23.5

4.23.6

4.24

4.25.1

4.8

4.6.1.1

60115-1

IEC

METHOD

60068-2-

21 (Ua1)

78 (Cab)

21 (Ub)

21 (Uc)

29 (Eb)

14 (Na)

30 (Db)

30 (Db)

20 (Ta)

13 (M)

6 (Fc)

2 (Ba)

1 (Aa)

TEST

IEC

Insulation resistance

Tensile all samples

number of samples

Climatic sequence:

Torsion other half

Low air pressure

remaining cycles

Voltage proof on

Rapid change of

Robustness of

(steady state)

(after ageing)

terminations:

(accelerated)

(accelerated)

Solderability

Solderability

Bending half

Temperature

temperature

of samples

Damp heat

Damp heat

Damp heat

Endurance

coefficient

(at 70 °C)

insulation

Vibration

1

Dry heat

Bump

TEST

st

Cold

cycle

For technical questions, contact:

Power Metal Film Leaded Resistors

Maximum voltage (DC) after 1 min; metal block

3 s; 245 °C; Solder bath method; SnAg3Cu0.5

for 3 s at 245 °C; solder bath (SnAg3Cu0.5)

acceleration 10 g; three directions; total 6 h

loaded with 0.01 P

2 s; 235 °C; Solder bath method; SnPb40

3 x 1500 bumps in three directions; 40 g

for 2 s at 235 °C; solder bath (SnPb40)

56 days; 40 °C; 90 % to 95 % RH;

during 1 min; metal block method

5 days; 55 °C; 95 % to 100 % RH

1000 h; loaded with P

Maximum voltage U

24 h; 55 °C; 90 % to 100 % RH

Between - 55 °C and + 155 °C

3 x 360° in opposite directions

Frequency 10 Hz to 500 Hz;

2 h; 8.5 kPa; 15 °C to 35 °C

8 h steam or 16 h 155 °C;

1.5 h ON and 0.5 h OFF

displacement 1.5 mm or

30 min at UCT; 5 cycles

leads immersed 6 mm:

30 min at LCT and

Load 5 N; 4 x 90°

Load 10 N; 10 s

PROCEDURE

16 h; 155 °C

2 h; - 55 °C

(3 x 2 h)

method

70

filmresistorsleaded@vishay.com

(Steps: 0 V to 100 V)

RMS

70

or U

= 500 V

max.

;

No damage ΔR max.: ± (0.5 % R + 0.05 Ω)

No damage ΔR max.: ± (0.5 % R + 0.05 Ω)

Vishay BCcomponents

PR01: ΔR max.: ± (1 % R + 0.05 Ω)

PR02: ΔR max.: ± (1 % R + 0.05 Ω)

PR03: ΔR max.: ± (2 % R + 0.05 Ω)

Good tinning (≥ 95 % covered);

Good tinning (≥ 95 % covered);

ΔR max.: ± (0.5 % R + 0.05 Ω)

ΔR max.: ± (1.5 % R + 0.1 Ω)

Number of failures: < 1 x 10

Number of failures: < 1 x 10

ΔR max.: ± (3 % R + 0.1 Ω)

ΔR max.: ± (5 % R + 0.1 Ω)

No breakdown or flashover

R

REQUIREMENTS

No visual damage

R

R

ins

≤ ± 250 ppm/K

ins

ins

No damage

no damage

no damage

min.: 1000 MΩ

min.: 10

min.: 10

PR01/02/03

3

4

MΩ

MΩ

www.vishay.com

-6

-6

123