1747314-1 TE Connectivity, 1747314-1 Datasheet - Page 66

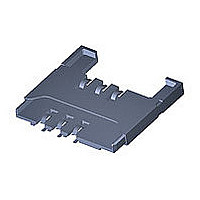

1747314-1

Manufacturer Part Number

1747314-1

Description

Manufacturer

TE Connectivity

Type

SIMr

Datasheet

1.1747314-1.pdf

(116 pages)

Specifications of 1747314-1

Gender

M

Mounting Style

Surface Mount

Termination Method

Solder

Body Orientation

Straight

Contact Pitch (mm)

2.54mm

Housing Material

Thermoplastic

Contact Material

Phosphor Bronze

Contact Pitch

2.54mm

Product Type

Connector

Card Type

2FF mini SIM

Card Guide Slots

With

Pcb Mount Style

Surface Mount

Contact Retention

No

Connector Stabilization Ribs

Without

Height Above Pc Board (mm [in])

1.96 [0.077]

Card Stop

With

Ejector Type

Push - Pull

Centerline (mm [in])

2.54 [0.100]

Durability Rating

5000 Cycles

Contact Base Material

Phosphor Bronze

Number Of Contacts

6

Housing Color

Black

Ul Flammability Rating

UL 94V-0

Card Insertion Style

Normal Insertion

Card Detection Switch

Without

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Reflow solder capable to 245°C

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Tape & Reel

Packaging Quantity

1,000/Reel

Lead Free Status / RoHS Status

Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

1747314-1

Manufacturer:

AMP

Quantity:

10 000

64

Products for Mobile Equipment

MID Technology

MID

Laser Direct Structuring Technology

Laser Direct Structuring (LDS) Technology

■

■

■

■

3D Part Design

Tyco Electronics provides its customers vast design expertise over a wide variety of manufac-

turing technologies. Our design engineers are experts in two shot design and product integration

for MID products. Optimal solutions are engineered with the appropriate MID technology to best

suit the application.

Modeling and Simulation

Tyco Electroniocs employs the most up

to date design tools available. We use

sophisticated 3D modeling and simulation

packages to accurately manufacture and

predict the end product.

■

■

■

■

All specifications subject to change. Consult Tyco Electronics for latest specifications.

Offers the ability to create parts with finer line width and spacing than conventional MID

processes will allow for.

The structure is molded in a standard single shot mold using one of several proprietary plastics

available.

Desired interconnect pattern is directly written on the resulting molded part and the conductive

paths are plated using industry standard methods.

The plating adheres only where the plastic has been activated by the laser.

Pro Engineer Wildfire 2.0 CAD software

Auto CAD 2005

MPA Moldflow to predict molding

behaviors

Pro Mechanica stress and thermal

analysis software

Catalog 1654270-2

Revised 8-2007