119790-8 TE Connectivity, 119790-8 Datasheet - Page 97

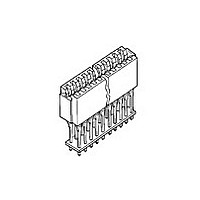

119790-8

Manufacturer Part Number

119790-8

Description

Manufacturer

TE Connectivity

Type

Card Edger

Datasheet

1.119790-8.pdf

(204 pages)

Specifications of 119790-8

Number Of Contacts

44POS

Body Orientation

Straight

Contact Plating

Gold

Contact Material

Phosphor Bronze

Termination Method

Solder

Mounting Style

Through Hole

Pitch (mm)

3.96mm

Housing Material

Polyester

Housing Color

Black

Product Line

AMP PACE

Product Type

Connector

Connector Type

Connector Assembly

Number Of Dual Positions

22

Housing Style

Closed End/Closed End - Standard

Post Alignment

Clear Polyester Contact Tip Strip

Proprietary Name

AMP PACE

Termination Post Length (mm [in])

4.57 [0.180]

Centerline (mm [in])

3.96 [0.156]

Row Spacing (mm [in])

5.08 [0.200]

Pre-assembled

Yes

Post Plating

Tin-Lead (30)

Pcb Mount Retention Type

Compliant Posts

Contact Plating, Mating Area, Material

Gold (30)

Contact Base Material

Phosphor Bronze

Underplate Material

Nickel

Connector Style

Card Edge

Ul Flammability Rating

UL 94V-0

Rohs/elv Compliance

Not ELV/RoHS compliant

Lead Free Solder Processes

Not relevant for lead free process

Lead Free Status / RoHS Status

Not Compliant

Catalog 1654080

Issued 7-03

www.tycoelectronics.com

The Reliable Plated Through-

Hole Interconnect

Solderless interconnections

have been popular in elec-

trical and electronic appli-

cation with world-wide

success for decades. They

provide reliable electrical

and mechanical stability

and offer applied-cost sav-

ings across the board. For

PC board applications,

ACTION PIN contacts from

Tyco Electronics provide

these features:

n

n

n

n

n

n

n

n

n

n

Since ACTION PIN contacts

do not have to be soldered,

issues associated with sol-

der are eliminated, such as:

Large gas-tight contact

zone

Reliability due to stored

energy in compliant pin

contacts

No damage to plated

through-holes during

installation

Especially suited for mul-

tilayer PC boards

Less costly board manu-

facturing due to larger

hole tolerances com-

pared to use of solid

pins

Application can be

made by end-user

Repairability—contact

can be replaced in the

same pin location (two

repairs)

Installation with no heat

cycling of board

Permits mass insertion

by minimizing forces

needed to insert pins as

compared to solid pin

press-fit application

Significant applied-cost

savings in many applica-

tions

• Faulty solder joints

• Solder fumes; cont-

aminant’s are

deposited on the

contacts

Dimensions are in inches and

millimeters unless otherwise

specified. Values in brackets

are metric equivalents.

Solderless press-fit inter-

connections using the

ACTION PIN contact are

primarily integrated in, but

not limited to, backplanes.

Solderless press-fit inter-

connections are used in

racks, especially where

connectors must be fixed

on the solder side of the PC

board and/or component

side. In these applications,

the holes for ACTION PIN

contact connectors are cov-

ered during the soldering

process and press-fitting is

performed after soldering.

Other applications for

ACTION PIN contact

interconnections include PC

boards that incorporate

components using surface

mount technology (SMT).

Here, too, press-fit intercon-

nections can be applied

after soldering, thus elimi-

nating complications

associated with connectors

suitable for surface

mounting.

Card Edge Connectors

(Solder Type, Board-to-Board)

ACTION PIN Press-Fit Contacts

• Solder spots; short

• Flux residuals

• Thermal strain on

• Degasing of plated

circuits between

printed circuits

printed circuit

boards and

components

through-holes

Dimensions are shown for

reference purposes only.

Specifications subject

to change.

Cross-Section Area from Tyco Electronics ACTION PIN Press-Fit

Contact in Printed Circuit Board Holes from Tyco Electronics.

Note: ACTION PIN contact mounting hole specifications are presented in

each product section, where applicable.

Principle of the Tyco

Electronics Compliant

ACTION PIN Contact

When an ACTION PIN con-

tact is inserted into a plated

through-hole, two spring

members are compressed,

exerting force against the

hole for gas-tight connec-

tion. The diameter of the

hole is smaller than the

diagonal size of the pin

(see cross-section illustra-

tion below).

The beam characteristics of

the pin are designed so

that a plastic, as well as an

elastic, deformation takes

place during insertion. The

two spring members com-

press to different degrees

USA: 1-800-522-6752

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425

.037 [0.94]

Minimum

Hole Dia.

to accommodate hole toler-

ances. The compliant pin

also reduces strain on the

board. With a rigid pin, the

elastic strain energy is

stored entirely in the board,

leading to damage of the

plated through-holes. With

the ACTION PIN contact,

the residual force of the

elastic deformation main-

tains stored energy to pro-

duce a tight contact zone

between the pin and the

plated through-hole. This

provides long term electri-

cal and mechanical reliabili-

ty of the interconnection.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

UK: 44-141-810-8967

Maximum

Hole Dia.

.043 [1.09]

97