DP-605NS OFF-WHITE 1.7 FL OZ 3M, DP-605NS OFF-WHITE 1.7 FL OZ Datasheet

DP-605NS OFF-WHITE 1.7 FL OZ

Specifications of DP-605NS OFF-WHITE 1.7 FL OZ

DP-605NS OFF-WHITE 1.7 FL OZ Summary of contents

Page 1

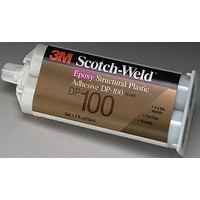

... Epoxy Adhesives DP-100 Clear DP-100 NS Translucent • Technical Data 3M™ Scotch-Weld™ Epoxy Adhesives DP-100 and DP-100NS are two-part Product Description adhesives offering fast cure and machinability. Available in larger containers like 3M™ Scotch-Weld™ Epoxy Adhesives 100 B/A or 100 NS B/A. Features • ...

Page 2

... Scotch-Weld ™ Epoxy Adhesives DP-100 Clear • DP-100 NS Translucent Typical Cured Note: The following technical information and data should be considered representative Properties Product Physical: Color Shore D Hardness (ASTM D 2240) Time to Handling Strength Cure Time Thermal: Wt. loss by Thermal Gravimetric Analysis Glass Transition Temp Coefficient of Thermal Expansion (in./in./° ...

Page 3

... Mixing and Applying For Duo-Pak Cartridges - 50 ml 3M™ Scotch-Weld™ DP-100 and DP-100 NS Adhesives are suppled in a dual syringe plastic Duo-Pak cartridge as part of the 3M™ Scotch-Weld™ EPX™ Applicator system. To use, simply insert the Duo-Pak cartridge into the EPX applicator and start the plunger into the cylinders using light pressure on the trigger ...

Page 4

... Scotch-Weld ™ Epoxy Adhesives DP-100 Clear • DP-100 NS Translucent Surface Preparation For optimum strength structural bonds, paint, oxide films, oils, dust, mold release agents and all other surface contaminants must be completely removed. However, the amount of surface preparation directly depends on the required bond strength and the environmental aging resistance desired by the user ...

Page 5

... Galvanized Steel- under the conditions specified. The following data shows typical results obtained with 3M™ Scotch-Weld™ Epoxy Adhesives DP-100 and DP-100 NS when applied to properly prepared substrates, cured for 7 days at 73°F (23°C) under 2 psi cure pressure, and tested according to the test methods indicated. ...

Page 6

... Scotch-Weld ™ Epoxy Adhesives DP-100 Clear • DP-100 NS Translucent Note: The following technical information and data should be considered representative Typical Adhesive Performance Characteristics Aluminum, T-peel (piw), tested @ 73°F (23°C) (psi) (continued) Aluminum etched Cold Rolled Steel Other Substrates, Overlap Shear tested @ 73°F (23°C) (psi) All cleaned by alcohol wipe, abrade, alcohol wipe. Note: The data shown here was generated using the 3M™ ...

Page 7

... Scotch-Weld ™ Epoxy Adhesives DP-100 Clear • DP-100 NS Translucent Typical Adhesive Note: The following technical information and data should be considered representative Performance Characteristics Environmental Resistance (continued) Aluminum (Etched) Measured by Overlap Shear tested 73°F (23°C) psi Environment 73°F (23°C)/50 days Water Vapor Solvent Resistance: (Visual check after immersion in specified solvent at 73° ...

Page 8

... Scotch-Weld ™ ™ Epoxy Adhesives DP-100 Clear • DP-100 NS Translucent Storage and Shelf Life Storage: Store products at 60-80°F (16-27°C) for maximum storage life. Rotate on Shelf Life: When stored as recommended in original unopened container, this Technical Information The technical information, recommendations and other statements contained in this document are based upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed ...