DP-270 CLEAR 1.7 FL OZ 3M, DP-270 CLEAR 1.7 FL OZ Datasheet - Page 6

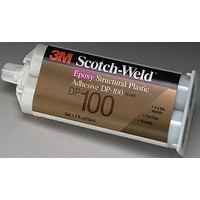

DP-270 CLEAR 1.7 FL OZ

Manufacturer Part Number

DP-270 CLEAR 1.7 FL OZ

Description

EPOXY 2 PART ADH CARTRIDGE 1.7FL.OZ

Manufacturer

3M

Series

Scotch Weldr

Datasheet

1.DP-270_BLACK_1.7_FL_OZ.pdf

(8 pages)

Specifications of DP-270 CLEAR 1.7 FL OZ

Adhesive Type

Epoxy - 2 Part

Adhesive Applications

Potting / Bonding - Electronic Components

Color

Clear

Dispensing Method

Dual-Cartridge

Volume

1.7fl.oz. (US)

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Application and

Equipment Suggestions

3M

Epoxy Potting Compound/Adhesive

DP270 Clear and Black

Handling/Curing

Information (continued)

™

Scotch-Weld

These products may be applied by spatula, trowel or flow equipment.

Two part mixing/proportioning/dispensing equipment is available for intermittent or

production line use. These systems are ideal because of their variable shot size and

flow rate characteristics and are adaptable to most applications.

3. For maximum bond strength apply product evenly to both surfaces to be joined.

4. Application to the substrates should be made within 70 minutes. Larger quantities

5. Join the adhesive coated surfaces and allow to cure at 60°F (16°C) or above until

6. The following times and temperatures will result in a full cure of these products.

7. Keep parts from moving during cure. Contact pressure necessary. Maximum shear

8. Excess uncured adhesive can be cleaned up with ketone type solvents*.

*Note: When using solvents, extinguish all ignition sources, including pilot lights,

Adhesion Coverage: A 0.005 in. thick bondline will yield a coverage of

and/or higher temperatures will reduce this working time.

firm. Heat up to 200°F (93°C) will speed curing.

strength is obtained with a 3-5 mil bond line.

™

and follow the manufacturer’s precautions and directions for use.

100°C (212°F)

23°C (73°F)

50°C (122°F)

80°C (176°F)

320 sq. ft./gallon

- 6 -

48 Hours

60 Minutes

30 Minutes

4 Hours