PRECISION COMPRESSION MOUNTING CLAMP SYSTEMS

Wakefield Engineering compression pack heat sinks and clamp systems provide electrical and

industrial equipment manufacturers with complete system solutions for proper installation

and heat dissipation for high-power compression pack semiconductor. All components for

All other products, please contact factory for price, delivery, and minimums.

144 Series

These high-quality mounting clamp assemblies are the worldwide standard for mounting,

compression, and clamping press-pack SCR, thyristor, rectifier, and other high power disc

packaged devices utilized in power distribution equipment, industrial controls, transportation

systems, and power supply and conversion systems.

Clamp assemblies will accommodate devices with overall case diameters to 5.25 in. (133.4

mm) maximum. Vertical device mounting space available for assemblies is determined by

selecting an appropriate series crossbar by length which, when a series spring assembly is

Clamp Assembly

130 Series

139 Series

143 Series

145 Series

146 Series

131/132/133 Series

Precision Compression

Clamp Systems

S e r i e s

130 SERIES

Order Guide:

Order Crossbar and Spring Assembly

Notes:

1. Spring assemblies are stainless steel leaves with a force indicator

separately by type number from table.

130 SERIES SPRING ASSEMBLY

130-1

130-2

130-3

130-4

130-5

Crossbar Device Mounting, Surface to Spring Assembly

130-A

130-B

130-C

130-D

130-E

130-F

130-G

130-H

130-J

130-K

130-L

130-M

130-N

130-P

Top Surface Dimension

130 SERIES CROSSBAR

800 lb - 2,000 lb (362.8 kg - 907.2 kg)

gauge, except the lowest cost Type 130-1 spring assembly manufac -

tured from automotive grade stainless steel.

Model

Model

No.

No.

Leaves

3,000 lbs (1,360.8 kg) and 5,000 lbs (2,268.0 kg)

No. of

8,000 lbs (3,628.8 kg) - 16,000 lbs (7,257.5 kg)

2,000 lbs (907.2 kg) - 10,000 lbs (4,535.9 kg)

1,000 lbs (453.6 kg) - 6,000 lbs (2,721.6 kg)

1,000 lbs (453.6 kg) - 6,000 lbs (2,721.6 kg)

2

2

3

4

5

800 lbs (362.9 kg) - 2,000 lbs (907.2 kg)

H i g h - P e rformance Press Pack Heat Sinks

4.22 (107.2) - 4.60 (116.8)

4.34 (122.9) - 5.22 (132.6)

5.15 (130.8) - 5.53 (140.5)

5.46 (138.7) - 5.84 (147.3)

5.77 (146.6) - 6.15 (156.2)

4.53(115.1) - 4.91 (124.7)

1.74 (44.2) -

2.05 (52.1) -

2.36 (59.9) -

2.67 (67.8) -

2.98 (75.7) -

3.29 (83.6) -

3.60 (91.4) - 3.98 (101.1)

3.91 (99.3) - 4.29 (109.0)

Compression Mounting Clamp Assemblies for Semiconductors to 2.25 in. (57.2mm) Diameter

Min.

Maximum Clamping Force

0.90 (22.9)

0.50 (12.7)

0.61 (15.5)

0.72 (18.3)

0.83 (21.1)

“X” Dimension

“Z”Dim.

in. (mm)

In. (mm)

Force Range

2.12 (53.8)

2.43 (61.7)

2.74 (69.6)

3.05 (77.5)

3.36 (85.3)

3.67 (93.2)

Max.

2,000 (907.2)

2,000 (907.2)

1,200 (544.3)

1,600 (727.8)

Max Force

800 (362.8)

lb (kg)

Dimensions:

lb. (kg)

in. (mm)

0.418 (189.60)

0.427 (193.68)

0.437 (198.22)

0.447 (202.76)

0.461 (209.11)

0.476 (215.91)

0.486 (220.45)

0.497 (225.44)

0.534 (242.22)

0.544 (246.75)

0.559 (253.56)

0.51 (231.33)

0.52 (235.87)

lbs. (grams)

0.4 (181.44)

0.331 (150.14)

0.333 (151.05)

0.408 (185.07)

Weight

0.219 (99.34)

0.19 (86.18)

lbs (gms)

Weight

58

device mounting and cooling are available separately for all standard compression require-

ments from 800 lbs (362.9 kg) to 16,000 lbs (7,257.5 kg) force in both natural and forced

convection applications.

selected (based on maximum clamping force required), will provide the necessary vertical

spring assemblies are designed with a force indicator gauge.

clearance space. For the 130 and 139 Series, this determination is made by subtracting the

chosen spring assembly “Z” dimension (refer to dimensional tables) from the crossbar

assembly “X” dimension minimum and maximum values, to calculate the available device

mounting space clearance for the particular assembly combination. Spring assembly “Z”

dimension is the dimension measured from the spring assembly device mounting surface to

the spring assembly top surface. Some series have fixed dimensions for alpha characters. All

Maximum Diameter (Ref)

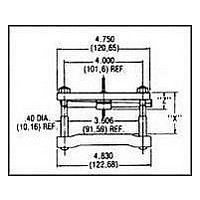

MECHANICAL DIMENSIONS

Power Disc Device

2.25 in. (57.2 mm)

3.50 in. (88.9 mm)

3.50 in. (88.9 mm)

4.00 in. (101.6 mm)

4.50 in. (114.3 mm)

5.25 in. (133.4 mm)

Dimensions: in. (mm)

Crossbar Stud Centerline

to Centerline Dimension

2.750 in. (69.9 mm) Ref

4.000 in. (101.6 mm) Ref

4.000 in. (101.6 mm) Ref

4.625 in. (117.5 mm) Ref

5.500 in. (139.7 mm) Ref

6.000 in. (152.4 mm) Ref

Normally stocked