S2663-1ED EVERETT CHARLES TECH, S2663-1ED Datasheet - Page 17

S2663-1ED

Manufacturer Part Number

S2663-1ED

Description

TEST SPRING SOCKET, PCB

Manufacturer

EVERETT CHARLES TECH

Series

S2663r

Datasheet

1.A-A-S-R.pdf

(20 pages)

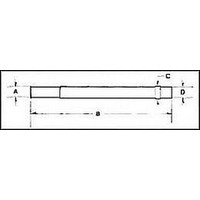

Specifications of S2663-1ED

Connector Type

Test Point

Length

0.760"

Body Material

Gold-Lined Nickel Silver

Contact Material

Beryllium Copper

Current Rating

3A

Contact Plating

Gold

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

.052 (1.32)

P2447 Specifications

HC125A-TT (replaceable probe) Specifications

minimum internal resistance and/or high current-carrying capacity.

These objectives are achieved by making the Pogo plunger and terminal as a single

unit. This construction method eliminates the resistance of the spring and body.

.095 (2.41)

Plunger . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nickel-plated hardened BeCu

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brass

Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless steel

Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . Nickel-plated brass

Electrical Resistance . . . . . . . . . . . . . . . . . . <10mΩ

Maximum Current . . . . . . . . . . . . . . . . . . . . 10 amps

Working Travel . . . . . . . . . . . . . . . . . . . . . . . .200 (5.08)

Spring Force in oz. (grams)

Standard: . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 (170)

The recommended hole is .1570 (#22 drill) for epoxy mounting.

Plunger . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gold-plated hardened BeCu

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gold-plated nickel silver

Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Silver-plated stainless steel

Electrical Resistance . . . . . . . . . . . . . . . . . . <20mΩ

Maximum Current . . . . . . . . . . . . . . . . . . . . 45 amps

Plunger Travel (Full) . . . . . . . . . . . . . . . . . . .250 (6.35)

The HC125A-TT is designed to be used with the SR125 receptacle. The recommended

mounting hole is .141/.143 (3.58/3.63mm). The recommended drill is a 3.6mm. Use

tool T125-0 for installation.

Spring Force in oz. (grams)

Standard: . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 (170)

.052 (1.32) x .188 (4.78) Deep

Terminal Moves with Plunger

.071 (1.80)

.040 (1.02)

.100 (2.54)

.092 (2.34)

.140 (3.56)

Low

.156 (3.96)

1.320 (33.53)

1.145 (29.08)

.020 (0.51)

Ω

/P2447/HC125A-TT

Initial

Initial

Low resistance Pogo Contacts are

designed for applications requiring

.030 (0.76)

.172 (4.37)

.144 (3.66)

Working

14.0 (397)

Working

16.0 (454)

.270 (6.89)

.445 (11.30)

.145 (3.68)

.100 (2.54)

.187 (4.75)

.156 (3.96)

90°

Dimensions in inches (millimeters).

15