R452.375 Littelfuse Inc, R452.375 Datasheet

R452.375

Manufacturer Part Number

R452.375

Description

Surface Mount Fuse

Manufacturer

Littelfuse Inc

Series

452r

Specifications of R452.375

Fuse Current

375mA

Fuse Size

6.10 X 2.69 X 2.69mm

Peak Reflow Compatible (260 C)

No

Current Rating

375mA

Body Material

Ceramic

Fuse Terminals

SMD Caps

Leaded Process Compatible

No

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

R452.375

Manufacturer:

AMP

Quantity:

38 080

NANO

The NANO

over the NANO

fuse design helps solve the problem of nuisance “opening” by accommo-

dating inrush currents that normally cause a fast-acting fuse to open.

ELECTRICAL CHARACTERISTICS:

AGENCY APPROVALS:

of Underwriters Laboratories and Certified by CSA.

AGENCY FILE NUMBERS:

INTERRUPTING RATINGS:

50 amperes at 125 VAC/VDC

ENVIRONMENTAL SPECIFICATIONS:

Operating Temperature:

Shock:

6 milliseconds).

Vibration:

Salt Spray:

Insulation Resistance (After Opening):

Method 302, Test Condition A, (10,000 ohms minimum).

Resistance to Soldering Heat:

(3 sec. at 260°C).

Thermal Shock:

Test Condition B (–65 to 125°C).

Moisture Resistance:

High Humidity (90-98 RH), Heat (65°C).

PHYSICAL SPECIFICATIONS:

Materials:

Soldering Parameters:

Solderability:

PACKAGING SPECIFICATIONS:

RS481-1 (IEC 286, part 3); 1,000 per reel; 5,000 piece reel also available.

Marking:

“T” to designate time delay characteristics.

PATENTED

ORDERING INFORMATION:

R452.375

R452.500

R452.750

R452 001.

R452 01.5

R452 002.

R452 02.5

R452 003.

R452 03.5

R452 004.

R452 005.

Catalog # Catalog # Rating

Tin-Lead

% of Ampere

Plated

Rating

100%

200%

300%

800%

MIL-STD-202, Method 213, Test Condition I (100 G’s peak for

Wave Solder — 260°C, 3 seconds maximum

Reflow Solder — 230°C, 30 seconds maximum

2

The 452/454 series Slo-Blo fuse marking includes the letter

Slo-Blo fuse has enhanced inrush withstand characteristics

MIL-STD-202, Method 201 (10–55 Hz, .06 in. total excursion).

Body: Ceramic

Terminations: Tin-Lead Alloy or Silver

Plated Brass Caps.

MIL-STD-202, Method 101, Test Condition B (48 hrs.).

2®

0454.375

0454.500

0454.750

0454 001.

0454 01.5

0454 002.

0454 02.5

0454 003.

0454 03.5

0454 004.

0454 005.

2

Plated

Silver

Fast-Acting fuse. The unique time delay feature of this

MIL-STD-202, Method 208.

Slo-Blo

MIL-STD-202, Method 107,

4 hours, Minimum

1 second, Min.; 60 seconds, Max.

0.2 seconds, Min.; 3 seconds, Max.

0.02 seconds, Min.; 0.1 seconds, Max.

Ampere Voltage

MIL-STD-202, Method 106,

®

Recognized under the Components Program

3/8

1/2

3/4

1

2

3

–55°C to 125°C.

Fuse 452/454 Series

1

2

3

4

5

1

1

1

/

/

/

2

2

2

UL E10480, CSA LR 29862.

MIL-STD-202, Method 210,

Rating

12mm Tape and Reel per EIA-

125

125

125

125

125

125

125

125

125

125

125

Opening

Time

MIL-STD-202,

Resistance Melting I

Cold Ohms

Nominal

1.20

0.700

0.360

0.225

0.0930

0.0625

0.0450

0.0340

0.0224

0.0186

0.0136

Next

w w w . l i t t e l f u s e . c o m

Nominal

A

15.0

20.16

26.53

34.40

53.72

2

0.101

0.240

0.904

1.98

3.65

8.20

Sec.

2

t

Refer to pg. 271 for SMF Omni-Blok

Average Time Current Curves

1000

0.01

100

0.1

10

Previous

1

0.1

Recommended pad layout

(.077")

1.96

(.270")

(.124")

(.116")

6.86

3.15

2.95

1

Surface Mount Fuses

CURRENT IN AMPERES

Subminiature Surface Mount

10

®

Holder, Series 154 000T.

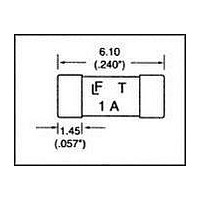

(.057")

1.45

F

(.240")

100

1 A

6.10

(.106")

2.69

T

®

(.106")

269

2.69

1000

®

7