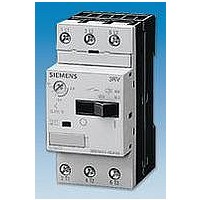

3RV10110JA10 SIEMENS, 3RV10110JA10 Datasheet - Page 51

3RV10110JA10

Manufacturer Part Number

3RV10110JA10

Description

CIRCUIT-BR, 0.70/1A

Manufacturer

SIEMENS

Series

3RVr

Datasheet

1.3RV19011A.pdf

(56 pages)

Specifications of 3RV10110JA10

No. Of Poles

3

Voltage Rating Vac

690V

Mounting Type

DIN Rail (EN 50022)

Approval Bodies

UL, CSA, VDE

Breaking Capacity Current Ac

100kA

Current Max

1.00A

Current Min

0.70A

External Depth

81mm

■

Overview

(1) Connection for mounting onto contactors:

(2) Selector switch for manual/automatic RESET and RESET button:

(3) Switch position indicator and TEST function of the wiring:

(4) Motor current setting:

(5) STOP button:

(6) Transparent, sealable cover:

(7) Supply terminals:

The 3RU11 thermal overload relays up to 100 A have been

designed for current-dependent protection of loads with normal

starting

rises due to overload or phase failure. An overload or phase

failure results in an increase of the motor current beyond the set

motor rated current. Via heating elements, this current rise heats

up the bimetal strips inside the device, which then bend and as

a result trigger the auxiliary contacts by means of a tripping

mechanism. The auxiliary contacts then switch off the load by

means of a contactor. The break time depends on the ratio

between the tripping current and set current I

the form of a long-term stable tripping characteristic

Characteristic

The "tripped" status is signaled by means of a switch position

indicator

manually or automatically after the recovery time has elapsed

(see LV 1 T,

The devices are manufactured in accordance with

environmental guidelines and contain environmentally friendly

and reusable materials.

They comply with all important worldwide standards and

approvals.

Optimally adapted in electrical, mechanical and design terms to the

contactors, these connecting pins can be used for direct mounting of

the overload relays. Stand-alone installation is possible as an

alternative (in some cases in conjunction with a stand-alone

installation module).

With this switch you can choose between manual and automatic

RESET. A device set to manual RESET can be reset locally by pressing

the RESET button. A remote RESET is possible using the RESET

modules (accessories), which are independent of size.

Indicates a trip and enables the wiring test.

Setting the device to the rated motor current is easy with the large

rotary knob.

If the STOP button is pressed, the NC contact is opened. This switches

off the contactor downstream. The contactor is switched on again

when the STOP button is released.

Secures the motor current setting, TEST function and the selector

switch for manual/automatic RESET against adjustment.

The generously sized terminals permit connection of two conductors

with different cross-sections for the main and auxiliary circuits. The

auxiliary circuit can be connected with screw-type terminals and

alternatively with spring-loaded terminals.

(see LV 1 T, Function)

(see LV 1 T,

Function).

Curves).

Function). Resetting takes place either

against excessive temperature

e

and is stored in

(see LV 1 T,

■

■

Benefits

The most important features and benefits of the 3RU11 thermal

overload relays are listed in the overview table

Relays, General

Application

Industries

The 3RU11 thermal overload relays are suitable for customers

from all industries who want to guarantee optimum inverse-time

delayed protection of their electrical loads (e.g. motors) under

normal starting conditions (CLASS 10).

Application

The 3RU11 thermal overload relays have been designed for the

protection of three-phase and single-phase AC and DC motors.

If single-phase AC or DC loads are to be protected by the 3RU11

thermal overload relays, all three bimetal strips must be heated.

For this purpose, all main circuits of the relay must be connected

in series.

Ambient conditions

The 3RU11 thermal overload relays have temperature

compensation in accordance with IEC 60947-4-1 for the

temperature range of –20 to +60 °C. For temperatures from

+60 to +80 °C the upper setpoint value of the setting range must

be reduced by the factor listed in the table below.

"Increased safety" type of protection EEx e according to

ATEX guideline 94/9/EC

The 3RU11 thermal overload relays are suitable for the overload

protection of explosion-proof motors with "increased safety" type

of protection EEx e. The relays meet the requirements of

EN 60079-7 (Electrical apparatus for potentially explosive

atmospheres – Increased safety "e").

The basic safety and health requirements of ATEX guideline

94/9/EG are fulfilled by compliance with

• EN 60947-4-1

• EN 60947-5-1

• EN 60079-14: 1997-02

• EN 60079-17: 1996-12

EU type test certificate for Category (2) G/D exists. It has the

number DMT 98 ATEX 6001.

Ambient temperature in °C

+60

+65

+70

+75

+80

3RU1 Thermal Overload Relays

Data).

3RU11 for standard applications

Overload Relays

Derating factor for

the upper setpoint value

1.0

0.94

0.87

0.81

0.73

Siemens LV 1 · 2006

(see Overload

5/51