UWE-15/5-Q12P-C Murata Power Solutions Inc, UWE-15/5-Q12P-C Datasheet - Page 19

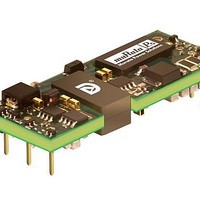

UWE-15/5-Q12P-C

Manufacturer Part Number

UWE-15/5-Q12P-C

Description

DC/DC TH Q12-15V UWE

Manufacturer

Murata Power Solutions Inc

Series

UWEr

Type

Isolated with Remote On/Offr

Datasheet

1.UWE-3.320-Q12PB-C.pdf

(23 pages)

Specifications of UWE-15/5-Q12P-C

Output

15V

Number Of Outputs

1

Power (watts)

75W

Mounting Type

Through Hole

Voltage - Input

9 ~ 36V

Package / Case

8-DIP Module, 1/8 Brick

1st Output

15 VDC @ 5A

Size / Dimension

2.30" L x 0.90" W x 0.38" H (58.4mm x 22.9mm x 9.7mm)

Power (watts) - Rated

75W

Operating Temperature

-40°C ~ 85°C

Efficiency

91.5%

Approvals

CAN, CSA, EN, IEC, UL

Product

Isolated

Output Power

75 W

Input Voltage Range

9 V to 36 V

Input Voltage (nominal)

12 V

Output Voltage (channel 1)

15 V

Output Current (channel 1)

5 A

Isolation Voltage

1.5 KV

Package / Case Size

C77

Output Type

Isolated

Output Voltage

15 V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

3rd Output

-

2nd Output

-

4th Output

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

811-2227-5

Soldering Guidelines

Murata Power Solutions recommends the specifi cations below when installing these

converters. These specifi cations vary depending on the solder type. Exceeding these

specifi cations may cause damage to the product. Your production environment may dif-

fer; therefore please thoroughly review these guidelines with your process engineers.

Input Fusing

Certain applications and/or safety agencies may require the installation of

fuses at the inputs of power conversion components. Fuses should also be

used if the possibility of sustained, non-current-limited, input-voltage polarity

reversals exist. For MPS UWE DC/DC Converters, you should use fast-blow type

fuses, installed in the ungrounded input supply line. Refer to the specifi cations

for fuse values.

be observed by the installer. For system safety agency approvals, the convert-

ers must be installed in compliance with the requirements of the end-use

safety standard, e.g., IEC/EN/UL60950-1.

Input Undervoltage Shutdown and Start-Up Threshold

Under normal start-up conditions, devices will not begin to regulate until

the ramping-up input voltage exceeds the Start-Up Threshold Voltage. Once

operating, devices will not turn off until the input voltage drops below the

Undervoltage Shutdown limit. Subsequent re-start will not occur until the input

is brought back up to the Start-Up Threshold. This built in hysteresis prevents

any unstable on/off situations from occurring at a single input voltage.

For Sn/Ag/Cu based solders:

Maximum Preheat Temperature

Maximum Pot Temperature

Maximum Solder Dwell Time

For Sn/Pb based solders:

Maximum Preheat Temperature

Maximum Pot Temperature

Maximum Solder Dwell Time

Wave Solder Operations for through-hole mounted products (THMT)

TECHNICAL NOTES

All relevant national and international safety standards and regulations must

115° C.

270° C.

7 seconds

105° C.

250° C.

6 seconds

www.murata-ps.com

Start-Up Time

The V

the ramping input voltage crosses the Start-Up Threshold and the fully loaded

output voltage enters and remains within its specifi ed accuracy band. Actual

measured times will vary with input source impedance, external input/output

capacitance, and load. The UWE Series implements a soft start circuit that

limits the duty cycle of its PWM controller at power up, thereby limiting the

input inrush current.

nominal input voltage applied but is turned off via the On/Off Control pin. The

specifi cation defi nes the interval between the point at which the converter is

turned on and the fully loaded output voltage enters and remains within its

specifi ed accuracy band. Similar to the V

to V

external load capacitance.

V

Input Source Impedance

UWE converters must be driven from a low ac-impedance input source.

The DC/DC’s performance and stability can be compromised by the use of

highly inductive source impedances. For optimum performance, compo-

nents should be mounted close to the DC/DC converter. If the application

has a high source impedance, low V

external input capacitance.

I/O Filtering, Input Ripple Current, and Output Noise

All models in the UWE Converters are tested/specifi ed for input refl ected ripple

current and output noise using the specifi ed external input/output components/

circuits and layout as shown in the following two fi gures.

elements, minimizing line voltage variations caused by transient IR drops in

conductors from backplane to the DC/DC. Input caps should be selected for bulk

capacitance (at appropriate frequencies), low ESR, and high rms-ripple-current

ratings. The switching nature of DC/DC converters requires that dc voltage

sources have low ac impedance as highly inductive source impedance can affect

system stability. In Figure 2, C

specifi c system confi guration may necessitate additional considerations.

OUT

The On/Off Control to V

The difference in start up time from V

External input capacitors (C

OUT

is therefore insignifi cant.

IN

V

IN

start-up time is also governed by the internal soft start circuitry and

to V

OSCILLOSCOPE

+

–

OUT

C

C

L

BUS

IN

BUS

TO

Start-Up Time is the interval of time between the point at which

= 33μF, ESR < 700mΩ @ 100kHz

= 12μH

= 220μF, ESR < 100mΩ @ 100kHz

Figure 2. Measuring Input Ripple Current

C

BUS

OUT

L

BUS

BUS

start-up time assumes the converter has its

IN

14 Mar 2011 MDC_UWE Series.A28 Page 19 of 23

in Figure 2) serve primarily as energy-storage

and L

Eighth-Brick DC/DC Converters

BUS

IN

CURRENT

IN

models can benefit from increased

IN

simulate a typical dc voltage bus. Your

PROBE

to V

C

to V

IN

OUT

OUT

email: sales@murata-ps.com

and from On/Off Control to

start-up, the On/Off Control

UWE Series

Wide Input, Isolated

+INPUT

–INPUT