8-215570-4 Tyco Electronics, 8-215570-4 Datasheet - Page 15

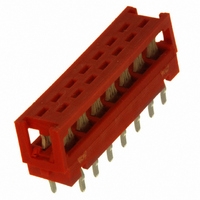

8-215570-4

Manufacturer Part Number

8-215570-4

Description

CONN PADDLEBRD 14POS VERT 28AWG

Manufacturer

Tyco Electronics

Series

Micro-MaTchr

Specifications of 8-215570-4

Connector Type

Ribbon Cable

Number Of Positions

14

Pitch

0.100" (2.54mm)

Number Of Rows

2

Row Spacing

0.100" (2.54mm)

Mounting Type

Through Hole

Cable Termination

Solder

Wire Gauge

28 AWG, Stranded or Solid

Features

Feed Through

Contact Finish

Tin

Color

Red

Number Of Positions Loaded

All

Contact Termination

IDC / IDT

Gender

Plug

No. Of Contacts

14

Pitch Spacing

1.27mm

Contact Plating

Tin

Colour

Red

Connector Mounting

RoHS Compliant

Product Type

Plugs - PCB

Number Of Positions / Contacts

12

Mounting Style

Through Hole

Termination Style

Solder Pin

Housing Material

Thermoplastic Polyester

Contact Material

Phosphor Bronze

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Contact Finish Thickness

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

Other names

A99421TR

.

QUALITY ASSURANCE PROVISIONS

4.1

4.1.1

Samples shall be released in accordance with applicable instruction sheets. They shall be selected at

random from production. At least 5 connectors of the 6 positions or at least 30 contacts shall be used for

each testgroup.

4.1.2

Qualification inspection shall be verified by testing samples as specified in spec. 108-19052 Par 3.7.

4.2

If changes significantly affecting form, fit or function are made to the product or the manufacturing

process, product assurance shall co-ordinate requalification testing, consisting of all or part of the original

testing sequence as determined by development/product, quality and reliability engineering.

4.3

Acceptance is based on verification that the product meets the requirement of par 3.6. Failures attributed

to equipment, test set-up or operator deficiencies shall nor disqualify the product. When product failure

occurs, corrective action shall be taken and samples resubmitted to qualification. Testing to confirm

corrective action is required before submittal.

4.4

The applicable AMP quality inspection plan will specify the samples acceptable quality level to be used.

Dimensional and functional requirements shall be in accordance with applicable product drawing and this

specification.

Rev. F

R6-77 (Rev. 07-01)

Sample selection:

Test sequence

Qualification testing:

Requalification testing

Acceptance.

Quality Conformance Inspection

Page 15 of 15

108-19052