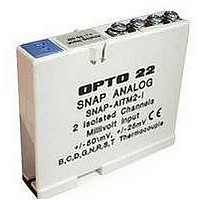

SNAP-AITM OPTO 22, SNAP-AITM Datasheet - Page 2

SNAP-AITM

Manufacturer Part Number

SNAP-AITM

Description

I/O Module

Manufacturer

OPTO 22

Type

Inputr

Specifications of SNAP-AITM

Accessory Type

Thermocouple Module

Leaded Process Compatible

No

Peak Reflow Compatible (260 C)

No

Signal Input Type

-150 To 150mV / -75 To 75mV

No. Of Analog Inputs

2

Brand/series

SNAP Series

Connection To Host

Backplane

Current, Input

170 mA

Dimensions

82.55mmL×18.29mmW×90.17mmH

Input

-150 to +150/-75 to +75 mVDC

Input Type

Analog

Input, Range

-150 to +150/-75 to +75 mVDC

Mounting Type

PCB

Number Of Channels

2

Number Of Inputs

2 Channels

Primary Type

Control

Resistance, Input

100 Megohms

Special Features

Transformer Isolation, Optical Isolation, Thermocouple Input

Standards

UL, CSA, CE Certified

Temperature, Operating

0 to +70 °C

Time, Response

66 ms

Voltage, Isolation

1500 V

Voltage, Supply

5 VDC

For Use With

SNAP PAC System

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

PAGE

2

Transformer and Optical Isolation

All SNAP analog input modules are transformer isolated and

optically isolated from all other modules and from the SNAP I/O

processor. The modules in this data sheet do not have channel-to-

channel isolation, however. (If you need isolated analog modules,

see Opto 22 form #1182.)

Optical isolation provides 4,000 volts of transient (4,000 V for

1 ms) protection for sensitive control electronics from industrial

field signals.

Transformer isolation prevents ground loop currents from

flowing between field devices and causing noise that produces

erroneous readings. Ground loop currents are caused when two

grounded field devices share a connection, and the ground

potential at each device is different.

IMPORTANT: Since these analog input modules provide multiple

single-ended input channels with a common reference, the

channels are not isolated from each other. (See Opto 22 form #1182

for isolated modules.)

Installation

Note module and processor compatibility in the following table:

All modules can be used with SNAP PAC rac ks and can be placed in

any position on the rack. Two- and four-channel modules can also

be used with legacy SNAP M-series and B-series mounting racks.

(For more information on using legacy hardware, see form #1688,

the SNAP PAC System Migration Technical Note.)

Modules snap securely into place in the row of connectors on the

mounting rack. Each module connector has a number. Analog input

modules and other types of SNAP I/O modules are mounted on the

module connectors starting at module position zero.

Modules require a special tool (provided) for removal.

32-channel inputs

8-channel inputs

4-channel inputs

2-channel inputs

Modules

SNAP PAC R-series controllers and

SNAP PAC brains

SNAP PAC R-series controllers and

SNAP PAC brains

Also the following legacy brains:

SNAP Ethernet, SNAP Simple, SNAP

Ultimate; SNAP-DNP-ASDS; SNAP OEM

SNAP PAC R-series controllers and

SNAP PAC brains

Also the following legacy brains:

SNAP Ethernet, SNAP Simple, SNAP

Ultimate; SNAP-DNP-ASDS; SNAP OEM;

serial SNAP brains (B3000, Modbus,

Profibus); B3000-HA; B6

Compatible I/O Processors

The following diagram shows part of a SNAP PAC mounting rack.

1. Place the rack so that the module connector numbers are right-

2. Position the module over the module connector, aligning the

3. With the module correctly aligned, push on the module to snap

4. (Optional) Use standard 4-40 x 1/4 truss-head Phillips hold-

5. Follow the wiring diagrams beginning on

For faster, easier field wiring installation and maintenance, use

SNAP TEX cables and breakout boards. See Opto 22 form #1756,

the SNAP TEX Cables & Breakout Boards Data Sheet, for compatibility

and specifications.

SNAP Analog Input Modules

Processor connector

side up, with zero on the left, as shown in the diagram above.

(If your rack has screw connectors, the screw connectors will be

at the bottom.)

small slot at the base of the module with the retention bar on

the rack. When positioning modules next to each other, be sure

to align the male and female module keys at the tops of the

modules before snapping a module into position.

it into place.

down screws to secure both sides of each module.

CAUTION: Do not over-tighten screws.

modules to the devices they monitor. Most modules accept up

to 14 AWG wire; the SNAP-AITM-8 accepts a maximum of two

solid 18 AWG wires.

Module

position zero

Module connectors

page 3

Retention bar

to attach