589181000000018 AVX Corporation, 589181000000018 Datasheet - Page 22

589181000000018

Manufacturer Part Number

589181000000018

Description

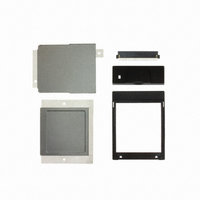

KIT COMPACT FLASH 50 POS

Manufacturer

AVX Corporation

Series

9181r

Datasheet

1.589181000000018.pdf

(24 pages)

Specifications of 589181000000018

Accessory Type

Compact Flash Kit

For Use With/related Products

Compact Flash - Type II

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

478-4690

589181000000018

Q3289372

589181000000018

Q3289372

INSERTION FORCE AFTER THE THIRD

EXCHANGE OF A CONTACT

Due to the very low strain on the PCB hole an

exchange of pins in one hole is possible up to

3 times without a significant loss of retaining

force. Contacts can be exchanged at any posi-

tion within a press-in connection.

TRANSITION RESISTANCE

A significant advantage of the high push-out

force and the large contact area (contact length

min 1.4 mm or 2 mm for a 3.2 mm PCB) is the

very low transition resistance (≤ 0.2 mΩ) as well

as the vibration and corrosion free connection.

Given that the transition resistance between

male and female connectors in accordance

with DIN 41611 can be up to 20 mΩ, the

transition resistance of the press-in connection

can be virtually neglected.

AVX can guarantee a secure connection within

a frequency range of 10 - 2000 Hz at 20 G in

accordance with IEC 48 (sec) 334.

In the right hand picture we show

the contact length of the VARIPIN

into an 3.2 mm PC board. These

show a large connection surface

from section 1 to section 4 which

corresponds to a contact length of

more than 2 mm.

PRESS-FIT INSTALLATION METHODS

Right angle headers and receptacle connectors require a

press-in tool.

Vertical headers and receptacles do not require a special tool.

They are installed using the “Flat Rock” method. Flat Rock

20

Press-Fit Technology Overview

Section 1

Force

Section 2

Transition Resistance before and after SO

20

98

80

60

40

%

2

1

termination involves the use of a flat metal plate, slightly

larger than the length and width of the connector. Installed in a

press, the plate pushes down on the connector in a uniform

manner until the connector is properly seated.

100

80

90

70

50

40

30

20

10

[N]

60

●

●

●

●

●

●

1

2

3

1

2

3

0.1

●

1 = first push in, push out

2 = second push in, push out

3 = third push in, push out

Diagonal 1.24 mm

0.94

●

●

●

●

●

●

Section 3

●

0.2

●

●

Drilled hole

Metallized hole

Diagonal

VARIPIN

●

●

1.0

SO

Before SO

Push in force

Push out force

(mOhm)

2

Section 4

1.09 hole Ø (mm)

2

2

1.15 mm

1.0 mm

1.24mm

±0.03

Test

Section 5