SX100GD2 SENSYM, SX100GD2 Datasheet - Page 5

SX100GD2

Manufacturer Part Number

SX100GD2

Description

PRESSURE SENSOR, 0-100PSI

Manufacturer

SENSYM

Datasheet

1.SX30DN.pdf

(10 pages)

Specifications of SX100GD2

External Depth

11.94mm

External Length / Height

13.84mm

External Width

13.97mm

Hysteresis

0.5%

Lead Spacing

2.54mm

Linearity

0.2%

Operating Pressure Range

0 To 100psig

Operating Temperature Max

85°C

APPLICATION INFORMATION

General

The SX family of pressure sensors functions

as a Wheatstone bridge. When pressure is

applied to the device (see Figure I) the

resistors in the arms of the bridge change

by an amount ∆.

The resulting differential output voltage V 0

is easily shown to be V O = V B x ∆. Since

the change in resistance is directly pro-

portional to pressure, V O can be written as:

Where: V O is the output voltage in mV

V OS is the offset error (the differential output

voltage when the applied pressure is zero).

The offset voltage presents little problem in

most applications, since it can easily be

corrected for in the amplifier circuitry, or

corrected digitally if a microprocessor is

used in the system.

Temperature effects

In this discussion, for simplicity of notation,

the change of a variable with temperature

will be designated with a dot (•) over the

variable. For example,

From equation (1), and ignoring the V OS

term, it in seen that for a given constant

pressure, the output voltage change, as a

function of temperature*, is:

Thus, in order for output voltage to be inde-

pendent of temperature, the voltage across

the bridge, V B , must change with tempera-

ture in the "opposite direction” from the

sensitivity change with temperature. From

the typical curves for the temperature

dependence of span (span = S x P x V B ),

July 2008 / 052

S

•

V O = S x P x V B ± V OS

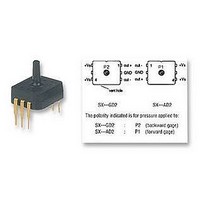

Figure I. Button sensor bridge

=

S is the sensitivity in mV/V per psi

P is the pressure in psi

V B is the bridge voltage in volts.

change in sensitivity

change in temperature

•

V O = SPV B

•

schematic

(1)

=

(2)

δS

δT

it can be seen that the sensitivity change

with temperature is slightly non-linear and

can be correlated very well with an equation

of the form:

where T D is the temperature difference

between 25°C and the temperature of inte-

rest, S O is the sensitivity at 25°C, and beta

(ß) and rho (ρ) are correlation constants.

Fortunately, between 0°C and 70°C the

change in sensitivity with temperature is

quite linear, and excellent results can be

obtained over this temperature range by

ignoring the second-order temperature

dependent term. Operating outside the 0°C

and 70°C temperature range will require a

more rigorous mathematical approach and

the use of non-linear compensating cir-

cuitry, if accuracy of better than ±1 % is re-

quired. Because the majority of SX appli-

cations fall within the 0°C to 70°C operating

temperature range, the discussion and

circuit designs given here will ignore the

non-linear effects.

Thus:

Substituting equation (4) into equation (1)

and ignoring V OS , it can be shown that the

necessary bridge voltage, V B , will be of the

form:

V B =

where V BO is the bridge voltage at 25°C.

However, for the temperature range of

interest, and since ß is small (0.215%/°C

from the electrical tables), the above

expression can be approximated by:

with less than 1 % error. Thus to compen-

sate for a negative 2150 ppm/°C sensitivity

change with temperature, the bridge voltage

should increase with temperature at a rate

of +2150 ppm/°C.

The above value of bridge voltage change

will be used in the circuit discussions that

follow. That is to say, the required change

in terms of ppm/°C is:

The bridge input resistance*, R B also

changes with temperature and is quite linear

in the temperature range of interest. The

bridge resistance has a temperature

coefficient of typically:

( )

( )

S = S O [(1 - ßT D ) + ρT D 2 ]

S = S O (1 - ßT D )

This equation is again non-linear.

V B =V BO [1 +ßT D ]

R B

R B

V BO

(1-ßT D)

•

V B

V B

•

= V BO [(1 - ßT D + (ßT D )

= +2050 ppm/°C

= +750 ppm/°C

2

+...)]

(3)

(4)

This term enters into several compensation

circuit equations, particularly when the

bridge excitation is from a constant current

source.

To summarize, the following list indicates

how the sensor variables can be accommo-

dated

• Full-scale span from device to device.

• Temperature coefficient of span:

• Offset voltage:

• Offset voltage temperature coefficient:

Bridge compensation circuits

Although thermistors can be used to tempe-

rature compensate the bridge (and in fact

will be required for extended temperature

operation), they are inherently non-linear,

difficult to use in volume production, and

more expensive than the circuit approaches

shown here, which use inexpensive semi-

conductor devices The circuits shown have

been designed to incorporate a minimum

number of adjustments and allow inter-

changeability of devices with little variation

from device to device. In general, equations

for the bridge voltage and its change with

temperature are given to enable the user to

modify or adjust the circuitry as required.

1. Diode string (Figure II)

For systems using 6 V supplies, this method

of compensating for the effects of span over

temperature is the lowest cost solution The

diodes are small signal silicon diodes, such

as 1N914 or 1N4148, and do not have to

be matched.

www.sensortechnics.com

Make the gain adjustment in the op amp

circuitry

1) temperature compensate the bridge or

2) temperature compensate the op amp

Adjustment in op amp circuitry

Usually can be ignored. For more precise

design requirements, contact the factory

for information on how to compensate for

this term.

gain

Figure II. Diode String Span

Pressure sensors

Compensation

SX Series

5/10