79875 AMPHENOL RF, 79875 Datasheet - Page 2

79875

Manufacturer Part Number

79875

Description

TNC PLUG CLAMP/SOLDER RG-58

Manufacturer

AMPHENOL RF

Series

TNCr

Type

Cable Plugr

Specifications of 79875

Connector Style

TNC

Connector Type

Plug, Male Pins

Contact Termination

Clamp and Solder

Impedance

50 Ohm

Mounting Type

Free Hanging (In-Line)

Fastening Type

Threaded

Cable Group

RG-58, 58C, 141, Belden 89907, 7806A

Frequency - Max

11GHz

Frequency-max

11GHz

Body Style

Straight Plug

Coaxial Termination

Solder / Clamp

Rg Cable Type

RG-55, 58, 141, 142, 223, 400

Contact Material

Brass

Angle

Straight

Application

Commercial

Cable Type

RG-58/U,RG/U 141,58,58C,55,142,223,400

Contact Plating

Silver

Finish, Housing

Nickel

Gender

Male

Material, Contact

Brass

Material, Dielectric

TFE/Delrin

Material, Housing

Brass

Mating Type

Threaded

Primary Type

TNC

Temperature, Range

-65 to +165 °C

Termination

Solder

Voltage, Rating

500 V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Features

-

Color

-

Lead Free Status / Rohs Status

RoHS Compliant part

Other names

ARF1082

Assembly Instructions-C36

TNC

CRIMP-CRIMP TYPES

Amphenol Corporation Tel: 800-627-7100

Step 1

Step 2

Step 3

36825

31-2318

31-2367

31-2367-RFX

31-2368

31-2373

31-2381

31-4452

31-2242

31-2242-RFX

31-2264

31-2264-RFX

31-2264-RFX

31-2315

31-2315-RFX

31-2317

31-2318

31-2368-RFX

31-2368-RFX

31-2381

31-2382

31-2383

31-2389

31-2389-RFX

31-2367-RFX

31-5849-RFX

31-6000-RFX

31-6001-RFX

31-6002-RFX

31-6003-RFX

outer ferrule should butt here

Amphenol

Number

contact must butt against cable dielectric

For RG-174, 179, 187, 188, 316/U cables only, slit jacket back .100"(2.5mm)

as shown. Before attaching center contact, slide metal spacer/TFE

sleeve (not shown) over cable dielectric. The center contact

should butt against the dielectric and TFE sleeve.

TNC Plug

TNC Bulkh. Jack

TNC Plug

TNC Plug

TNC Plug

TNC Plug

TNC Angle Plug

TNC Plug

TNC Plug

TNC Plug

TNC Blkh Jack

TNC Blkh Jack

TNC Blkh Jack

TNC Plug

TNC Plug

TNC Jack

TNC Blkh Jack

TNC Plug

TNC Plug

TNC Angle Plug

TNC Angle Plug

TNC Angle Plug

TNC Blkh Jack

TNC Blkh Jack

TNC Plug

TNC Angle Plug

TNC Plug

TNC Plug

TNC Angle Plug

TNC Angle Plug

Connector

Type

58, 141

174, 188, 316

58, 141

58, 141, 142A

59, 62

55, 142, 223

55, 142, 223, 400

142, 400

179,187

179,187

59,62,140,210

59

62

174,188

174,188,316

174.188

174,187,188

59

62

55,142

58,141

62

58,141

141,142

58,141

58,58c

8x,LMR240

B8214, B9913

LMR 400, B9913,B9914

8x,LMR240

cable dielectric must butt insulator

RG-/U

Cable

outer ferrule

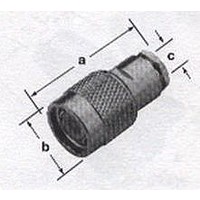

a

This part is used only with RG-62 cable

b

.068(1.7)

.068(1.7)

.068(1.7)

.068(1.7)

.068(1.7)

.068(1.7)

.068(1.7)

.068(1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068 (1.7)

.068

Solder

.068

Solder

Solder

Solder

Cavity for

Contact

c

bushing

Outer Ferrule

male contact

.213(5.4)

.178(4.5)

.213(5.4)

.213(5.4)

.255(6.5)

.213(5.4)

.213(5.4)

.213(5.4)

.178 (4.5)

.178 (4.5)

.255 (8.5)

.255 (8.5)

.255 (8.5)

.178 (4.5)

.178 (4.5)

.178 (4.5)

.178 (4.5)

.255 (8.5)

.255 (8.5)

.213 (5.4)

.213 (5.4)

.255 (8.5)

.213 (5.4)

.213 (5.4)

.213

.213

.255

.429

.429

.255

Cavity for

310

Hex Crimp Data

Step 1 Strip cable jacket, braid, and dielectric to dimensions

Step 2 Flare slightly end of cable braid as shown to facilitate

Step 3 Install cable assembly into body assembly so that inner

Tool 227-944

plug body assembly

227-1221-11

227-1221-09

227-1221-11

227-1221-11

227-1221-13

227-1221-11

227-1221-11

227-1221-11

227-1221-09

227-1221-09

227-1221-13

227-1331-13

227-1331-13

227-1221-09

227-1221-09

227-1221-09

227-1221-09

227-1221-13

227-1221-13

227-1221-11

227-1221-11

227-1221-13

227-1221-11

227-1221-11

227-1221-11

227-1221-11

227-1221-13

227-1221-25

227-1221-25

227-1221-13

in table above. All cuts are to be sharp and square.

Important: Do not nick braid, dielectric, and center

conductor. Slide outer ferrule onto cable as shown.

insertion of inner ferrule. Important: Do not comb out braid.

Place contact on cable center conductor so that it butts

against cable dielectric. Crimp contact in place using

Die Set Cavity indicated in table above.

ferrule portion slides under braid. Push cable assembly

forward until contact snaps into place in insulator. Slide

outer ferrule over braid and up against connector body.

Crimp outer ferrule using Die Set Cavity in table above.

Die Set for

CTL Series

Tool No.

CTL-1

CTL-2

CTL-1

CTL-1

CTL-1

CTL-1

CTL-1

CTL-1

CTL-2

CTL-2

CTL-1

CTL-1

CTL-1

CTL-2

CTL-2

CTL-2

CTL-2

CTL-1

CTL-1

CTL-1

CTL-1

CTL-1

CTL-1

CTL-1

CTL-1,5

CTL-1,3,5

CTL-1,5

CTL-4

CTL-4

CTL-1,5

.593(15.1)

.593(15.1)

.593(15.1)

.630(16.0)

.593(15.1)

.593(15.1)

.578(14.7)

.593(15.1)

.593(15.1)

.590(15.0)

.593(15.1)

.689(17.5)

.689(17.5)

.593(15.1)

.590(15.0)

.590(15.0)

.590(15.0)

.630(16.0)

.630(16.0)

.578(14.7)

.578(14.7)

.689(17.5)

.593(15.1)

.689(17.5)

.630 (16.0)

.709(18)

.630 (16)

.630 (16)

.728 (18.5)

.728 (18.5)

Stripping Dimensions, inches (mm)

a

Amphenol

.250(6.4)

.250(6.4)

.250(6.4)

.303(7.7)

.250(6.4)

.250(6.4)

.328(8.3)

.250(6.4)

.250(6.4)

.323(8.2)

.250(6.4)

.362(9.2)

.362(9.2)

.250(6.4)

.323(8.2)

.323(8.2)

.323(8.2)

.303(7.7)

.303(7.7)

.328(8.3)

.328(8.3)

.362(9.2)

.250(6.4)

.362(9.2)

.303 (7.7)

.382(9.7)

.303 (7.7)

.303 (7.7)

.401 (0.2)

.401 (10.2)

b

www.amphenolrf.com

.156(4.0)

.156(4.0)

.156(4.0)

.156(4.0)

.156(4.0)

.156(4.0)

.125(3.2)

.156(4.0)

.156(4.0)

.118(3.0)

.156(4.0)

.157(4.0)

.197(5.0)

.156(4.0)

.118(3.0)

.118(3.0)

.118(3.0)

.157(4.0)

.197(5.0)

.125(3.2)

.125(3.2)

.156(4.0)

.156(4.0)

.157(4.0)

.157 (4.0)

.161(4.1)

.157 (4.0)

.157 (4.0)

.244 (6.2)

.244 (6.2)

c

®