OXYMAC50.V.2 Honeywell, OXYMAC50.V.2 Datasheet - Page 2

OXYMAC50.V.2

Manufacturer Part Number

OXYMAC50.V.2

Description

Flow Sensors Board Interface KGZ/GMS 0-100%

Manufacturer

Honeywell

Datasheet

1.OXYMAC50.A.2.pdf

(4 pages)

Specifications of OXYMAC50.V.2

Accuracy/reliability

+/- 2 % Full Scale

Supply Voltage

24 V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Oxymac50, DE800 and Elecdit

TECHNICAL DATA

Measuring range

Power source

Other inputs

Power consumption (interface)

Outputs

Accuracy

Resolution

Operating temperature

Storage temperature

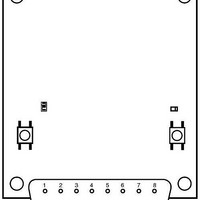

Dimensions

Connector

Mates with type

Notes: For warm up time and other sensor characteristics refer to datasheet 100470-EN

(1)

OPERATING AND CALIBRATION NOTES

Oxymac50

1. Reset of the Oxymac50 is possible by putting the power off/on.

2. The output signal can be 0 V to 10 V or 4 mA to 20 mA. The output signal is factory set by the solder bridge JP1.

3. A proper operation of a connected sensor and electronic circuit can be tested with the test switch or with an external signal.

4. LED indication - proper sensor operation is indicated by blinking of LED D3.

5. Calibration - sensor and Oxymac circuit can be calibrated in normal air. After a loss of power the Oxymac50 circuit stores the

DE800

1. Heater adjustment - the heater voltage of the sensor can be adjusted with pot meter PC419.

2. Test function - after pressing the test button, the output has to go to a 20% lower output signal. Testing with an external (24 V)

3. Calibration - the sensor can be calibrated in normal air with the calibration button. Calibration is lost after power loss.

4. LED -if the sensor is functioning properly, the LED D4 is blinking.

5. Signal out - if the sensor is functioning properly a pulse signal can be measured at terminal K2.

Elecdit

Adjustment/calibration procedure. The interface is factory set, for sensor replacement follow these instructions.

1. Adjust with Pot1 12 V (internal ±6 V) at Pin 2.

2. Adjust with Pot2 reference at Pin 1 to 10 V ±0.2 V.

3. After approx 60 s an impulse (blinking) signal should be present at Pin 1. Apply at the sensor 95 mbar air, adjust with Pot5 at

4. Adjust with Pot4 0 mV at Pin 10.

5. Adjust with Pot5 Uout to 0 V at Pin 9.

2

After switching the test function the output signal should indicate a 20 % lower value.

calibration value.

signal is possible via terminal TE.

Pin 9 to 0.8 V. Then apply at the sensor 1013 mbar air and adjust with Pot3 at Pin 9 Uout to 8.3 V.

Factory set to voltage or current output

www.honeywell.com/sensing

Oxymac50

+24 Vdc ±20 %

Ext Calibration, Sensor Pump,

Sense and Common, Test

<250 mW

0 V to 10 V, 4 mA to 20 mA

63 mm x 108 mm,

4 mm Ø mounting holes

15 pin male D connector

(1)

DE800

0 % to 25 % oxygen (standard)

0 % to 100 % oxygen (option)

+24 Vdc ±20 %

Ext Calibration, Sensor Pump,

Sense, Common, Heater, Test

<500 mW

4 mA to 20 mA, 0 V to 10 V

80 mm x 100 mm,

6,5 mm Ø mounting holes

Screw connector block

GMS-10, KGZ-10, KGZ-12

-10 °C to 60 °C

-10 °C to 50 °C

2 % full scale

0.04 V

(1)

, Pulse 0 V to 10 V, LED drive

Elecdit

Ext Calibration, Sensor Pump,

Sense and Common

<250 mW

60 mm x 42 mm x 17 mm

2 x 5 pin 2,5 mm x 2,5mm

±15 Vdc ±10 %