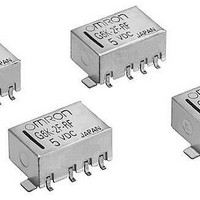

G6K-2F-RF-DC3 Omron, G6K-2F-RF-DC3 Datasheet - Page 6

G6K-2F-RF-DC3

Manufacturer Part Number

G6K-2F-RF-DC3

Description

Low Signal Relays - PCB 1GHz DPDT 3VDC

Manufacturer

Omron

Series

G6KRFr

Datasheet

1.G6K-2F-RF-S-DC5.pdf

(8 pages)

Specifications of G6K-2F-RF-DC3

Coil Type

Non-Latching

Coil Current

33 mA

Contact Form

2 Form C

Coil Voltage

3 VDC

Power Consumption

100 mW

Termination Style

Solder Terminal

Isolation

20 dB to 30 dB at 1 GHz

Insertion Loss

0.2 dB at 1 GHz

Maximum Switching Current

1 A

Contact Rating

0.3 A at 125 VAC, 1 A at 30 VDC

Contact Configuration

DPDT

Contact Current Max

1A

Contact Voltage Ac Nom

125V

Contact Voltage Dc Nom

30V

Coil Voltage Vdc Nom

3V

Coil Frequency Max

1GHz

Coil Resistance

91ohm

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

3DC G6K-2F-RF

Precautions

■ Recommended Soldering Method

1. Temperature Profile for Lead Solder (Measured at the PCB)

3. The thickness of cream solder to be applied should be between 200 and 250 μm and the land pattern should be based on Omron’s recommended

■ Precautions for correct use

For general precautions, refer to Omron’s Relay Technical guidelines, contained in Omron’s relay catalog.

Relay Handling

Do not unpack the relay until ready to mount it. Use the relay as soon as

possible after opening the moisture-proof bag. Otherwise, the terminals

may tarnish and seal failure may occur after the solder process.

When washing the product after soldering, use a water-based or

alcohol-based solvent. Keep the solvent temperature below 40°C.

Do not put the relay in a cold cleaning bath immediately after soldering.

Operating, Storage Environment

If the relay is stored for a long time in an adverse environment with high

temperature, high humidity, organic or sulfide gases, then sulfide or

oxide films will form on the contact surfaces. These films may result in

unstable contact, contact problems or function problems. Therefore,

operate, store or transport the product under specified environmental

conditions.

Coating

The relay mounted on the PCB may be coated or washed, but do not

apply silicone coating or detergent containing silicone, otherwise, the

silicone coating or detergent may remain on the surface of the relay.

Latching Relay Mounting

Make sure that excess vibration or shock doesn’t set or reset the

relay during normal operation. The relay is shipped in the ‘reset’

position. Shock or vibration during shipping may require the application

of a reset signal, prior to operation.

326

PCB pattern. To maintain the correct soldering joint shown in the following diagram, we recommend applying solder using the soldering conditions

shown above. Check the soldering in the actual mounting conditions prior to use.

1. Use in locations where the relay is not exposed to corrosive

2. Use in locations where no visible dust exists.

3. Use in locations where the product is not exposed to direct

4. Do not apply force to the product which may result in deformation

gas such as hydrogen sulfide gas or salty air.

sunlight, rain or snow.

or change in quality of the product.

220 to

180 to

High Frequency Relay

245

200

150

Preheating

90 to 120

PCB

Soldering

20 to 30

G6K-RF

Terminal

Time (s)

Relay

Solder

Land

2. Temperature Profile for Lead-free Solder (Measured at the PCB)

Claw Securing Force During Automatic Mounting

During automatic insertion of relays, make sure to set the securing

force of each claw to the following so that the relay’s characteristics

will be maintained.

Maximum Allowable Voltage

The maximum allowable voltage of the coil can be obtained from the

coil temperature increase and the heat-resisting temperature of the

coil insulating sheath material. (Exceeding the heat-resisting tem-

perature may result in burning or short-circuiting.) The maximum

allowable voltage also involves important restrictions which include

the following;

• Must not cause thermal changes in or deterioration of the insulating

• Must not cause damage to other control devices.

• Must not cause any harmful effect on people.

• Must not cause fire.

Therefore, be sure to use the maximum allowable voltage as specified in

the catalog. As a rule, the rated voltage must be applied to the coil. A

voltage exceeding the rated value, however, can be applied to the coil

providing that the voltage is less than or equal to the maximum allowable

voltage. It must be noted that continuous voltage application to the coil

will cause a coil temperature increase which may affect characteristics

such as electrical life and coil insulation.

Consider using a latching relay instead of a non-latching relay with a

continuous voltage applied to the coil.

material, which may result in films developing on the contacts.

Insufficient

amount of

solder

C

250 max.

230

180

150

B

Secure the claws to the shaded area. Do not

attach them to the center of the relay or just

one part of the relay.

Excessive

amount of

solder

Direction A: 1.96 N max.

Direction B: 4.90 N max.

Direction C: 1.96 N max.

120 max.

Preheating

Case top panel

(peak): 255°C max.

Soldering

30 max.

Relay terminal

section

Time (s)