Scotchlok

30000 Series

Data Sheet

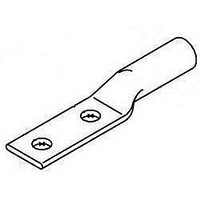

1. Product Description

Scotchlok

consist of a series of terminal lugs from 6

AWG through 1,000 kcmil (MCM) de-

signed for terminating copper conductors.

Each lug is tin plated to resist corrosion and

can be installed with standard industry tool-

ing. Chamfered ends ensure ease of inser-

tion and closed end barrels exclude mois-

ture.

The Scotchlok lugs consist of a series of

one-hole lugs from 6 AWG through 4/0,

one-hole long-barreled lugs from 2/0

through 500 kcmil and two-hole long-bar-

reled lugs from 4/0 through 1,000 kcmil.

The lug features are:

— One-piece, seamless tin-plated copper.

— Simple application using readily

— Chamfered ends for ease of conductor

— U.L. Listed, CSA Certified.

— Standard and long-barrel lugs with

2. Applications

— To terminate copper conductors from 6

— Indoor and outdoor.

— Low voltage and high voltage (up to

— Long-barreled lugs are available for

— For maximum secureness require-

available tools.

insertion.

one-hole pads and long-barrel lugs

with two-hole pads are available in

most sizes.

AWG through 1,000 kcmil.

35 kV).

extra crimping requirements.

ments, two-hole lugs are available in

large sizes.

Copper Compression Lugs

Copper Compression Lugs

3. Data

Physical and Electrical

The Scotchlok 30000 series copper lugs,

crimped with approved die sets, can be used

on cables with a rated operating temperature

of 90 C and an emergency overload rating

of 130 C.

The lugs pass the requirements of UL 486A,

Underwriters Laboratories standards for

safety. The current rating of these lugs meets

or exceeds the current rating of the conduc-

tor size for which it is intended.

A. Dimension

B. Crimping Tool-Die Recom-

4. Specifications

Product

Lugs must be constructed of seamless cop-

per and tin plated according to ASTM

B454–71, Class Cu/Sn8. They must be

available in one-hole standard-barreled

lengths from No. 6 AWG through 4/0, one-

hole long-barreled lengths from 2/0 through

500 kcmil (MCM) and two-hole long-bar-

reled lengths from 4/0 through 1,000 kcmil.

The lugs when crimped with the approved

die sets must have a current-carrying capac-

ity equal to the conductors for which they

are rated.

(see Table 1 on page 2)

mendations

(see Table 2 on page 3)

LISTED

540H

Engineering/Architectural

Lugs shall be crimped with one of the ap-

proved die sets according to the engineering

information supplied with the connectors.

(See Crimping Tool and Die Set Table). All

terminations of copper stranded wires in

sizes 6 AWG through 1,000 kcmil shall be

made electrically and mechanically secure

with Scotchlok Copper Compression Lugs.

The lugs must have a current-carrying ca-

pacity equal to the conductors they are rated

for and must also meet the requirements as

listed in U.L. 486A test standards.

5. Performance Tests

A. Physical and Electrical Properties

Material – Lug: Copper, C.D.A. 120

Voltage Rating – Low and High voltage

Current Rating – Same as each conductor

B. U.L. 486

Scotchlok lugs crimped with the approved

die sets pass the series of tests as found in

U.L. 486, Underwriters Laboratories stan-

dards for safety.

Plating: Tin plated, minimum

thickness 0.0001 inches

(up to 35 kV)

for which connector is

rated