TE-POWER-NODE Micropelt, TE-POWER-NODE Datasheet - Page 7

TE-POWER-NODE

Manufacturer Part Number

TE-POWER-NODE

Description

Power Management Modules & Development Tools THERMAL ENERGY HARVESTING DEV KIT

Manufacturer

Micropelt

Type

Energy Harvestingr

Datasheet

1.TE-POWER-NODE.pdf

(9 pages)

Specifications of TE-POWER-NODE

Input Voltage

0.27 V to 2 V

Output Voltage

2.4 V

Board Size

63 mm x 30 mm x 34 mm

Maximum Operating Temperature

+ 105 C

Operating Supply Voltage

0.27 V to 2 V

Product

Power Management Modules

Dimensions

63 mm x 30 mm x 34 mm

For Use With/related Products

MPG-D751

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

TE-POWER-NODE

Manufacturer:

Micropelt

Quantity:

135

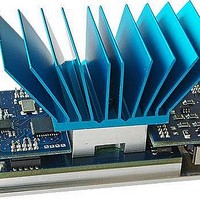

TE-Power NODE

4. Application of the TE-Power NODE

4.1 Attaching the Assembly to a Harvesting Target

Attachment of a thermoharvester to its target heat source is a critical factor in any application. The TE-Power NODE

helps to explore the effects of mounting pressure, surface flatness / roughness and various thermal interfaces

materials on the harvesting result. The base of the assembly attaches to the target either through magnetic force or

through 2 tapped mounting holes (M2.6).

4.2 Heatsink Positioning and Orientation

Both positioning and orientation of the TE-Power NODE are of major importance for the power yield, particularly

when the power density of the heat source is low. The alignment of the heatsink fins relative to the heat source

and the direction of natural convection deserves special attention. To help optimize this, the heatsink adaptor has

been designed so that the heatsink can be removed and then re-attached perpendicular to its default orientation.

Note that it is thermally inefficient to place the TE-Power NODE horizontally on top of a heat source (figure A)

where hot air warms the heat-sink. This reduces the effective temperature difference across the thermogenerator

thus lowering the thermovoltage and consequently the TEG’s power output. A forced air flow over the heatsink

instead maximizes power, regardless of position and orientation.

4.3 Radiation Suppression

Hot surfaces radiate in the infrared spectrum. This can cause the TE-Power NODE’s heatsink to heat up, diminish-

ing effective ΔT and thus the power output of the device. In such cases it may be helpful to cover the hot surface

near the TE-Power NODE such that radiation is inhibited. Alternatively, a block of thermally conductive material

may be used to increase the distance between radiating surface and heatsink, thereby improving natural convec-

tion.

www.micropelt.com | phone +49 761 156 337 0 | info@micropelt.com

Figure A: Inferior positioning

TE-Power NODE mounted on top

of the heat source, surrounded by

a bubble of warm air warming the

heatsink. This arrangement yields

low ΔT and low power output.

Self-powered, Wireless Sensor Node & Thermoharvesting Explorer

Figure B1: Preferred positioning

TE-Power NODE mounted on a

heatsink fins aligned horizon-

tally. Results in acceptable per-

formance.

vertical surface with the

Convection Stream

Smart Thermoharvesting

Figure B2: Ideal positioning

TE-Power NODE mounted on a vertical

surface with the heatsink fins aligned

vertically. This is best supporting natural

convection and results in the highest

possible ΔT and power output.

0039DSTPN75x0210v3e |

Page 7