AT3535SY9ZS-RV Kingbright Corp, AT3535SY9ZS-RV Datasheet

AT3535SY9ZS-RV

Specifications of AT3535SY9ZS-RV

Related parts for AT3535SY9ZS-RV

AT3535SY9ZS-RV Summary of contents

Page 1

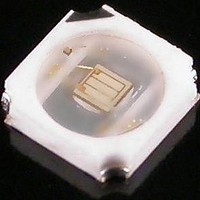

... The device has a single mounting surface. The device must be mounted according to the specifications. SPEC NO: DSAI6849 REV NO: V.4 APPROVED: WYNEC CHECKED: Allen Liu 3.5X3.5mm SMD LED WITH CERAMIC SUBSTRATE Part Number: AT3535SY9ZS-RV Super Bright Yellow Material as follows: Package : Ceramics Encapsulating resin : Silicone resin Electrodes : Ag plating DATE: APR/20/2009 DRAWN: D ...

Page 2

... Selection Guide Part No. AT3535SY9ZS-RV Super Bright Yellow (AlGaInP) Notes: 1. θ1/2 is the angle from optical centerline where the luminous intensity is 1/2 the optical centerline value. 2. Luminous intensity / luminous flux: +/-15%. Absolute Maximum Ratings at T Parameter DC Forward Current [1] Peak Forward Current [2] Power dissipation Operating Temperature ...

Page 3

... Super Bright Yellow SPEC NO: DSAI6849 REV NO: V.4 APPROVED: WYNEC CHECKED: Allen Liu 3.5X3.5mm SMD LED WITH CERAMIC SUBSTRATE AT3535SY9ZS-RV DATE: APR/20/2009 DRAWN: D.M.Su PAGE ERP: 1212000013 ...

Page 4

Reflow soldering is recommended and the soldering profile is shown below. Other soldering methods are not recommended as they might cause damage to the product. SPEC NO: DSAI6849 REV NO: V.4 APPROVED: WYNEC CHECKED: Allen Liu 3.5X3.5mm SMD LED WITH ...

Page 5

Recommended Soldering Pattern (Units : mm ; Tolerance: ± 0.1) Tape Dimensions (Units : mm) Reel Dimension SPEC NO: DSAI6849 REV NO: V.4 APPROVED: WYNEC CHECKED: Allen Liu 3.5X3.5mm SMD LED WITH CERAMIC SUBSTRATE DATE: APR/20/2009 DRAWN: D.M.Su PAGE: 5 ...

Page 6

... LEDs are transported, we recommend that you use the same packing methods as Kingbright’s. SPEC NO: DSAI6849 REV NO: V.4 APPROVED: WYNEC CHECKED: Allen Liu 3.5X3.5mm SMD LED WITH CERAMIC SUBSTRATE AT3535SY9ZS-RV DATE: APR/20/2009 DRAWN: D.M.Su PAGE ERP: 1212000013 ...

Page 7

JEDEC Moisture Sensitivity: Level Floor Life Time Conditions ≤ 30 ° weeks Notes: 1. CAUTION - The ‘‘accelerated equivalent’’ soak requirements shall not be used until correlation of damage response, including electrical, after soak and ...

Page 8

Handling Precautions Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible. Although its characteristic significantly reduces thermal stress more susceptible to damage by external mechanical force result, special handling precautions need ...

Page 9

Designing the Position of LED on a Board. 1.No twist/warp/bent/or other stress shall be applied to the board after mounting LED with solder to avoid a crack of LED package. Refer to the following recommended position and direction of LED. ...

Page 10

Reliability Test Items And Conditions The reliability of products shall be satisfied with items listed below Lot Tolerance Percent Defective (LTPD) : 10% No. Test Item 1 Continuous Operating Test 2 High Temperature Operating Test 3 Low Temperature Operating Test ...