SPX1117M3-L-2-5 Exar Corporation, SPX1117M3-L-2-5 Datasheet - Page 6

SPX1117M3-L-2-5

Manufacturer Part Number

SPX1117M3-L-2-5

Description

IC REG LDO 2.5V 800MA SOT223-3

Manufacturer

Exar Corporation

Series

-r

Datasheet

1.SPX1117M3-L-1-5.pdf

(11 pages)

Specifications of SPX1117M3-L-2-5

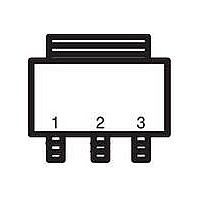

Package / Case

TO-261-4, TO-261AA, SOT-223-4

Regulator Topology

Positive Fixed

Voltage - Output

2.5V

Voltage - Input

Up to 15V

Voltage - Dropout (typical)

1.1V @ 800mA

Number Of Regulators

1

Current - Output

800mA

Current - Limit (min)

1A

Operating Temperature

-40°C ~ 125°C

Mounting Type

Surface Mount

Number Of Outputs

3

Polarity

Positive

Output Voltage

5 V

Output Type

Adjustable, Fixed

Dropout Voltage (max)

1.3 V

Output Current

800 mA

Load Regulation

0.2 %

Maximum Operating Temperature

+ 125 C

Mounting Style

SMD/SMT

Minimum Operating Temperature

- 40 C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

SPX1117M3-L-2-5/TR

Manufacturer:

Sipex Corporation

Quantity:

20 000

Part Number:

SPX1117M3-L-2-5/TR

Manufacturer:

SIPEX

Quantity:

20 000

APPLICATION INFORMATION

O

To ensure the stability of the SPX1117, an

output capacitor of at least 2.2µF (tantalum or

ceramic) or 10µF (aluminum) is required. The

value may change based on the application

requirements

temperature range. The value of ESR can vary

based on the type of capacitor used in the

applications

recommended value for ESR is 0.5Ω or less. A

larger value of output capacitance (up to

100µF)

response.

© 2010 Exar Corporation

UTPUT

V

V

IN

IN

=3.3V, V

=3.3V, V

Fig. 16: Load Step Response 0mA to 800mA

Fig. 17: Load Step Response 0mA to 800mA

C

can

APACITOR

OUT

OUT

Signal 1=V

Signal 1=V

=1.8V, C

=1.8V, C

to

improve

of

guarantee

OUT

OUT

IN

IN

the

=10µF, C

=10µF, C

, Signal 4=I

, Signal 4=I

the

output

OUT

OUT

=2.2µF, Ceramic

load

=2.2µF, OSCON

stability.

LOAD

LOAD

load

transient

The

or

8

8

6/11

0

0

0

0

m

m

S

The SPX1117 SOT-223 package is designed to

be compatible with infrared reflow or vapor-

phase reflow soldering techniques. During

soldering, the non-active or mildly active

fluxes may be used. The SPX1117 die is

attached to the heatsink lead which exits

opposite the input, output, and ground pins.

Hand soldering and wave soldering should be

avoided

damage to the device with excessive thermal

gradients

recommended

follows: vapor phase reflow and infrared

reflow with the component preheated to within

65°C of the soldering temperature range.

T

The thermal resistance of SPX1117 (SOT-223

package) is 15°C/W from junction to tab and

31°C/W from tab to ambient for a total of 46

°C/W from junction to ambient (Table 1). The

SPX1117 features the internal thermal limiting

to

conditions. Special care needs to be taken

during continuous load conditions such that

the maximum junction temperature does not

exceed 125 °C. Thermal protection is activated

at >155°C and deactivated at <140 °C.

Taking the FR-4 printed circuit board and 1/16

thick

experiment

effective at transmitting heat with the tab

attached to the pad area and a ground plane

HERMAL

OLDERING

A

A

protect

L

L

o

o

with

w

w

since

C

D

D

on

HARACTERISTICS

M

r

r

(fig.19),

1

o

the

o

ETHODS

p

the

p

soldering

these

ounce

o

o

u

u

device

Fig. 18

t

t

package.

V

V

the

o

o

methods

copper

l

l

t

t

a

a

method

PCB

during

g

g

e

e

The

S

S

R

R

foil

P

P

material

can

e

e

X

X

g

g

Rev. 2.0.0

SOT-223

overload

are

u

1

u

1

as

l

l

1

1

cause

a

a

1

t

1

t

o

o

an

as

7

7

is

r

r