MPX10GS Freescale Semiconductor, MPX10GS Datasheet - Page 4

MPX10GS

Manufacturer Part Number

MPX10GS

Description

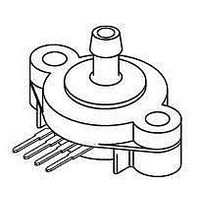

PRESSURE SENSOR GAUGE 4-SIP

Manufacturer

Freescale Semiconductor

Series

MPX10r

Datasheet

1.MPX10GP.pdf

(9 pages)

Specifications of MPX10GS

Pressure Type

Gauge

Operating Pressure

1.45 PSI

Output

0 ~ 35mV

Voltage - Supply

3V

Termination Style

PCB

Operating Temperature

-40°C ~ 125°C

Package / Case

4-SIP, Axial Port

Mounting Style

Through Hole

Maximum Operating Temperature

+ 125 C

Minimum Operating Temperature

- 40 C

Operating Supply Voltage

3 V

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

MPX10

4

Temperature Compensation

MPX10 series over temperature.

diaphragm, there are no temperature effects due to

differences in the thermal expansion of the strain gauge and

the diaphragm, as are often encountered in bonded strain

gauge pressure sensors. However, the properties of the

strain gauge itself are temperature dependent, requiring that

the device be temperature compensated if it is to be used

over an extensive temperature range.

achieved rather simply with additional resistive components,

or by designing your system using the MPX2010D series

sensor.

the equation: V

pressure range

calculating nonlinearity: 1) end point straight line fit or 2) a

least squares best line fit. While a least squares fit gives the

Figure 2

Because this strain gauge is an integral part of the silicon

Temperature compensation and offset calibration can be

Linearity refers to how well a transducer’s output follows

Pressure

70

60

50

40

30

20

10

Figure 3. Linearity Specification Comparison

0

0

shows the typical output characteristics of the

out

(Figure

Actual

= V

off

3). There are two basic methods for

LINEARITY

+ sensitivity x P over the operating

Pressure (kPa)

Linearity

Theoretical

PSI

kPa

80

70

60

50

40

30

20

10

0

0

V

Figure 2. Output vs. Pressure Differential

S

P1 > P2

MPX10

= 3 V

2.0

0.3

DC

Max

(V

(V

Offset

Span

OFF

FSS

P

)

)

OP

Pressure Differential

4.0

0.6

-40°C

Lead Frame

6.0

0.9

“best case” linearity error (lower numerical value), the

calculations required are burdensome.

(often more desirable in error budget calculations) and the

calculations are more straightforward for the user.

Freescale’s specified pressure sensor linearities are based

on the end point straight line method measured at the

midrange pressure.

in the basic chip carrier (Case 344). A silicone gel isolates the

die surface and wire bonds from the environment, while

allowing the pressure signal to be transmitted to the silicon

diaphragm.

characteristics and internal reliability and qualification tests

are based on use of dry air as the pressure media. Media

other than dry air may have adverse effects on sensor

performance and long term reliability. Contact the factory for

information regarding media compatibility in your

application.Refer to application note AN3728, for more

information regarding media compatibility.

Figure 4. Unibody Package — Cross-Sectional Diagram

Wire Bond

Conversely, an end point fit will give the “worst case” error

Figure 4

The MPX10 series pressure sensor operating

+25°C

8.0

1.2

illustrates the differential or gauge configuration

+125°C

Die Coat

Silicone

10

1.5

(Not to Scale)

Range

Offset

Span

(Typ)

(Typ)

Die

P1

P2

Freescale Semiconductor

Stainless Steel

Metal Cover

Sensors

RTV Die

Bond

Epoxy

Case