MS5535-CM Measurement Specialties Inc., MS5535-CM Datasheet

MS5535-CM

Specifications of MS5535-CM

Related parts for MS5535-CM

MS5535-CM Summary of contents

Page 1

... Bit data word from a pressure and temperature dependent voltage. Additionally the module contains 6 readable coefficients for a highly accurate software calibration of the sensor. MS5535C is a low power, low voltage device with automatic power down (ON/OFF) switching. A 3-wire interface is used for all communications with a microcontroller ...

Page 2

... Supply voltage Storage temperature Overpressure NOTE 1) Storage and operation in an environment of dry and non-corrosive gases. 2) The MS5535CM is qualified referring to the ISO Standard 6425 and can withstand an absolute pressure of 30 bar in salt water. DA5535C_003.doc 000055351195 ECN1118 Fig. 1: Block diagram MS5535C. Fig. 2: Pin configuration of MS5535C. ...

Page 3

... During conversion the sensor will be switched on and off in order to reduce power consumption; the total on time within a conversion is about 2 ms. 3) This value can be reduced by switching off MCLK while MS5535C is in standby mode strongly recommended that a crystal oscillator be used because the device is sensitive to clock jitter. A square-wave form of the clock signal is a must ...

Page 4

ELECTRICAL CHARACTERISTICS DIGITAL INPUTS Parameter Symbol Input High Voltage V IH Input Low Voltage V IL Signal Rise Time t r Signal Fall Time t f DIGITAL OUTPUTS Parameter Symbol Output High Voltage V OH Output Low Voltage V OL ...

Page 5

... PRESSURE OUTPUT CHARACTERISTICS With the calibration data stored in the interface IC of the MS5535C the following characteristics can be achieved: Parameter Resolution Absolute Pressure Accuracy (Temperature range 0 .. +40° C) Absolute Pressure Accuracy (Temperature range -40 .. +85° C) Absolute Pressure Accuracy (Temperature range -40 .. +125° C) ...

Page 6

... DA5535C_003.doc 000055351195 ECN1118 ADC-value D1 vs Pressure (typical) 6000 8000 10000 Pressure (mbar) ADC-value D2 vs Temperature (typical Temperature (°C) June 16th, 2008 -40° C 25° C 125° C 12000 14000 80 100 ...

Page 7

... Absolute Pressure Accuracy after Calibration, 1st order compensation 250 200 150 100 2000 4000 -50 -100 Absolute Pressure Accuracy after Calibration, 2nd order compensation 100 2000 4000 -50 -100 -150 -200 -250 DA5535C_003.doc 000055351195 ECN1118 6000 8000 10000 Pressure (mbar) 6000 8000 10000 ...

Page 8

... Temperature Error Accuracy vs temperature (typical -40 - DA5535C_003.doc 000055351195 ECN1118 Pressure Error Accuracy vs temperature (typical Temperature (° Temperature (° C) June 16th, 2008 Pres. error 4bar (1st order) Pres. error 4bar (2nd order) 100 120 Temperature error (standard calculation) Temperature error (with 2nd ...

Page 9

... DA5535C_003.doc 000055351195 ECN1118 Pressure error vs supply voltage (typical) 2.8 3 3.2 Voltage (V) Temperature error vs supply voltage (typical) 2.8 3 3.2 Voltage (V) June 16th, 2008 14000 mbar 6000 mbar 3.4 3.6 1000 mbar 3.4 3 ...

Page 10

... FUNCTION GENERAL The MS5535C consists of a piezoresistive sensor and a sensor interface IC. The main function of the MS5535C is to convert the uncompensated analogue output voltage from the piezoresistive pressure sensor to a 16-Bit digital value, as well as providing a 16-Bit digital value for the temperature of the sensor. ...

Page 11

... C4: Temperature coefficient of pressure offset C5: Reference temperature C6: Temperature coefficient of the temperature Read digital pressure value from MS5535B D1 (16 Bit) Read digital temperature value from MS5535B D2 (16 Bit) Calculate calibration temperature UT1 = 8*C5 + 10000 Calculate actual temperature Difference between actual temperature and reference ...

Page 12

... SECOND-ORDER TEMPERATURE COMPENSATION In order to obtain best accuracy over the whole temperature range recommended to compensate for the non-linearity of the output of the temperature sensor. This can be achieved by correcting the calculated temperature and pressure by a second order correction factor. The second-order factors are calculated as follows: dT < 0 ...

Page 13

... Fig. 1. The SCLK (Serial clock) signal initiates the communication and synchronises the data transfer with each Bit being sampled by the MS5535C on the rising edge of SCLK and each Bit being sent by the MS5535C on the rising edge of SCLK. The data should thus be sampled by the microcontroller on the falling edge of SCLK and sent to the MS5535C with the falling edge of SCLK. The SCLK-signal is generated by the microprocessor’ ...

Page 14

Conversion start for temperature measurement and ADC-data-out "D2": start of conversion sequence: START+T-measurement Bit0 Bit1 Bit2 Bit3 Bit4 Bit5 Bit6 Bit7 Bit8 Bit9 Start-bit Setup-bits Stop-bit Calibration data read out sequence for word 1/ word 3: sequence: coefficient read + ...

Page 15

... LIGHT SENSITIVITY The MS5535C is sensitive to sunlight, especially to infrared light sources. This is due to the strong photo effect of silicon. As the effect is reversible there will be no damage, but the user has to take care that in the final product the sensor cannot be exposed to direct light during operation. This can be achieved for instance by placing mechanical parts with holes in such that light cannot pass ...

Page 16

... DECOUPLING CAPACITOR Particular care must be taken when connecting the device to power supply µF tantalum capacitor must be placed as close as possible of the MS5535C's VDD pin. This capacitor will stabilise the power supply during data conversion and thus, provide the highest possible accuracy. APPLICATION EXAMPLE: DIVING COMPUTER SYSTEM USING MS5535C MS5535C is a circuit that can be used in connection with a microcontroller in diving computer applications ...

Page 17

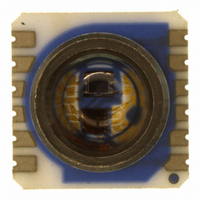

... DEVICE PACKAGE OUTLINES Fig. 8: Device package outlines of MS5535CM. DA5535C_003.doc 000055351195 ECN1118 June 16th, 2008 17 ...

Page 18

... RECOMMENDED PAD LAYOUT Pad layout for bottom side of MS5535C soldered onto printed circuit board Pad layout for top side of MS5535C soldered onto printed circuit board DA5535C_003.doc 000055351195 ECN1118 Fig. 9: Layout for bottom side Fig. 10: Layout for top side June 16th, 2008 ...

Page 19

... Special care has to be taken to not touch the protective gel of the sensor during the assembly. The MS5535C can be mounted with the cap down or the cap looking upwards. In both cases it is important to solder all contact pads. The Pins PEN and PV shall be left open or connected to VDD. Do not connect the Pins ...

Page 20

... The electrical contact pads are protected against ESD according HBM (human body model therefore essential to ground machines and personal properly during assembly and handling of the device. The MS5535C is shipped in antistatic transport boxes. Any test adapters or production transport boxes used during the assembly of the sensor shall equivalent antistatic material. ...

Page 21

... ORDERING INFORMATION Product Product Code 14 Pressure Sensor MS5535-CM Module with gel FACTORY CONTACTS Intersema Sensoric SA Ch. Chapons-des-Prés 11 CH-2022 BEVAIX SWITZERLAND NOTICE Intersema reserves the right to make changes to the products contained in this data sheet in order to improve the design or performance and to supply the best possible products. Intersema assumes no responsibility for the use of any circuits shown in this data sheet, conveys no license under any patent or other rights unless otherwise specified in this data sheet, and makes no claim that the circuits are free from patent infringement ...