AMMP-5618-BLK Avago Technologies US Inc., AMMP-5618-BLK Datasheet - Page 8

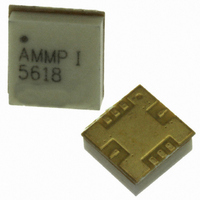

AMMP-5618-BLK

Manufacturer Part Number

AMMP-5618-BLK

Description

IC AMP GP HI PWR 6-20GHZ 8-SMD

Manufacturer

Avago Technologies US Inc.

Type

General Purpose Amplifierr

Datasheet

1.AMMP-5618-BLK.pdf

(9 pages)

Specifications of AMMP-5618-BLK

Gain

13dB

Current - Supply

107mA

Frequency

6GHz ~ 20GHz

Noise Figure

4.4dB

P1db

19dBm

Package / Case

8-QFN

Rf Type

DBS, LMDS, VSAT

Voltage - Supply

3 V ~ 5 V

Frequency Range

6GHz To 20GHz

Noise Figure Typ

4.4dB

Supply Current

107mA

Supply Voltage Range

5V

Rf Ic Case Style

SMD

No. Of Pins

8

Package

8SMD

Number Of Channels Per Chip

1

Typical Output Power

19 dBm

Typical Power Gain

13 dB

Maximum Operating Frequency Range

>=20000 MHz

Maximum Output Return Loss

12(Typ) dB

Typical Noise Figure

4.4 dB

Typical Output Intercept Point

30 dBm

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Test Frequency

-

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-1852

AMMP-5618-BLK

AMMP-5618-BLK

Available stocks

Company

Part Number

Manufacturer

Quantity

Price

Company:

Part Number:

AMMP-5618-BLK

Manufacturer:

Avago Technologies

Quantity:

135

Part Number:

AMMP-5618-BLK

Manufacturer:

AVAGO/安华高

Quantity:

20 000

Solder Reflow Profile

The most commonly used solder reflow method is ac-

complished in a belt furnace using convection heat

transfer. The suggested reflow profile for automated

reflow processes is shown in Figure 24. This profile is

designed to ensure reliable finished joints. However, the

profile indicated in Figure 1 will vary among different

solder pastes from different manufacturers and is shown

here for reference only.

Figure 24. Suggested Lead-Free Reflow Profile for SnAgCu Solder Paste.

8

300

250

200

150

100

50

0

0

Ramp 1

50

Preheat

Peak = 250 ±5°C

100

Ramp 2

Seconds

150

Reflow

Melting point = 218°C

200

Cooling

250

300

Stencil Design Guidelines

A properly designed solder screen or stencil is required

to ensure optimum amount of solder paste is deposited

onto the PCB pads. The recommended stencil layout is

shown in Figure 25. The stencil has a solder paste deposi-

tion opening approximately 70% to 90% of the PCB pad.

Reducing stencil opening can potentially generate more

voids underneath. On the other hand, stencil openings

larger than 100% will lead to excessive solder paste smear

or bridging across the I/O pads. Considering the fact that

solder paste thickness will directly affect the quality of

the solder joint, a good choice is to use a laser cut stencil

composed of 0.127 mm (5 mils) thick stainless steel which

is capable of producing the required fine stencil outline.

Figure 25. Stencil Outline Drawing (mm).

Figure 26. Combined PCB and Stencil Layouts (mm).

0.38

0.56

0.1

1.04

0.39

0.3

2.49

0.72

0.36