MBA02040C1620FRP00 Vishay, MBA02040C1620FRP00 Datasheet - Page 11

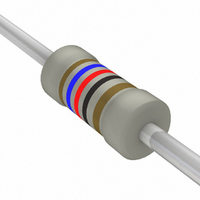

MBA02040C1620FRP00

Manufacturer Part Number

MBA02040C1620FRP00

Description

RES 162 OHM METL FILM .40W 1% T/

Manufacturer

Vishay

Series

5063JD Spacemiserr

Type

Professional Leaded Resistorr

Specifications of MBA02040C1620FRP00

Temperature Coefficient

±100ppm/°C

Resistance (ohms)

162

Power (watts)

0.4W

Composition

Metal Film

Tolerance

±1%

Size / Dimension

0.063" Dia x 0.142" L (1.60mm x 3.60mm)

Lead Style

Through Hole

Package / Case

Axial

Resistance In Ohms

162

Case

Axial

Resistance

162ohm

Resistance Tolerance

± 1%

Power Rating

400mW

Voltage Rating

200V

Resistor Element Material

Metal Film

Operating Temperature Range

- 55 C to + 155 C

Termination Style

Axial

Dimensions

1.6 mm Dia. x 3.6 mm L

Lead Free Status / RoHS Status

Contains lead / RoHS non-compliant

Features

-

Height

-

Lead Free Status / Rohs Status

Details

Other names

5063JD162R0F12AF5BC

BC162XTR

BC162XTR

MBA/SMA 0204, MBB/SMA 0207, MBE/SMA 0414 - Professional

Vishay Beyschlag

Note

(1)

(2)

(3)

(4)

www.vishay.com

32

TEST PROCEDURES AND REQUIREMENTS

CLAUSE

4.23

4.23.2

4.23.3

4.23.4

4.23.5

4.23.6

4.13

4.19

4.29

4.18.2

4.17

4.22

4.16

4.7

4.40

60115-1

± (0.4 % R + 0.05 Ω) for MBE/SMA 0414

± (0.8 % R + 0.05 Ω) for MBE/SMA 0414

± (0.2 % R + 0.05 Ω) for MBE/SMA 0414

± (0.4 % R + 0.05 Ω) for MBE/SMA 0414

IEC

METHOD

60068-2-

21 (Ua

30 (Db)

30 (Db)

14 (Na)

45 (XA)

21 (Ub)

21 (Uc)

20 (Tb)

20 (Ta)

13 (M)

2 (Ba)

1 (Aa)

6 (B4)

TEST

IEC

-

-

-

1

)

of temperature

Robustness of

soldering heat

Rapid change

Resistance to

Voltage proof

(human body

terminations

Solderability

Electrostatic

Damp heat,

Damp heat,

Component

sequence:

Short time

resistance

discharge

pressure

Vibration

Dry heat

overload

Climatic

Low air

solvent

model)

TEST

cyclic

cyclic

Cold

For technical questions, contact:

Professional Thin Film Leaded Resistors

30 min at LCT = - 55 °C

30 min at UCT= 155 °C

U = 2.5 x

6 h; 10 Hz to 2000 Hz

MBA/SMA 0204: 2 kV

MBB/SMA 0207: 4 kV

MBE/SMA 0414: 6 kV

Stability for product

types:

Tensile, bending and

solder bath method;

solder bath method;

1.5 mm or 196 m/s

Room temperature;

+ 23 °C; toothbrush

90 % to 100 % RH;

95 % to 100 % RH;

U = 2 x U

U

MBA/SMA 0204:

MBB/SMA 0207:

MBE/SMA 0414:

Isopropyl alcohol

IEC 61340-3-1;

3 pos. + 3 neg.

PROCEDURE

15 °C to 35 °C

55 °C; 5 days;

RMS

components;

+ 235 °C; 2 s

+ 245 °C; 3 s

155 °C; 16 h

8.5 kPa; 2 h;

(260 ± 3) °C;

SnAg3Cu0.5

55 °C; 24 h;

Unmounted

MBA/SMA 0204

MBB/SMA 0207

- 55 °C; 2 h

MBE/SMA 0414

500 cycles

200 cycles

100 cycles

(10 ± 1) s

5 cycles

5 cycles

SnPb40

method

1 cycle

torsion

= U

P

max.

ins

70

; 60 s

x R

; 5 s

or

2

filmresistorsleaded@vishay.com

± (0.5 % R + 0.05 Ω)

± (0.1 % R + 0.01 Ω)

± (0.1 % R + 0.01 Ω)

± (0.5 % R + 0.05 Ω)

± (0.1 % R + 0.01 Ω)

± (0.1 % R + 0.01 Ω)

± (0.1 % R + 0.01 Ω)

1 Ω to 2.4 MΩ

1 Ω to 332 kΩ

1 Ω to 1 MΩ

STABILITY

CLASS 0.5

no visible

no visible

no visible

damage

damage

damage

Good tinning (> 95 % covered, no visible damage)

PERMISSIBLE CHANGE (ΔR max.)

No flashover or breakdown

± (0.5 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (0.25 % R + 0.05 Ω)

± (0.5 % R + 0.05 Ω)

REQUIREMENTS

no visible damage

± (1 % R + 0.05 Ω)

Marking legible;

0.22 Ω to < 1 Ω

0.22 Ω to < 1 Ω

0.22 Ω to < 1 Ω

STABILITY

CLASS 1

no visible

no visible

no visible

damage

damage

damage

Document Number: 28766

± (0.5 % R + 0.05 Ω)

Revision: 23-Jul-10

STABILITY

± 0.5 % R

± 0.5 % R

± 0.5 % R

± 0.5 % R

± 0.5 % R

CLASS 2

> 332 kΩ

> 2.4 MΩ

no visible

no visible

no visible

± 2 % R

damage

damage

damage

> 1 MΩ