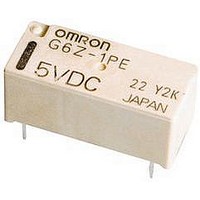

G6Z-1FE-A DC12 Omron, G6Z-1FE-A DC12 Datasheet - Page 14

G6Z-1FE-A DC12

Manufacturer Part Number

G6Z-1FE-A DC12

Description

RELAY HI FREQ 50 OHM SMD

Manufacturer

Omron

Series

G6Zr

Specifications of G6Z-1FE-A DC12

Relay Type

RF

Circuit

SPDT (1 Form C)

Contact Rating @ Voltage

0.01A @ 30VAC/DC

Coil Type

Standard

Coil Current

16.7mA

Coil Voltage

12VDC

Control On Voltage (max)

9 VDC

Control Off Voltage (min)

1.2 VDC

Mounting Type

Surface Mount

Termination Style

Gull Wing

Coil Frequency Max

2.6GHz

Coil Voltage Vdc Nom

12V

Contact Current Max

500mA

Contact Voltage Ac Nom

30V

Contact Voltage Dc Nom

30V

Coil Resistance

720ohm

Contact Configuration

SPDT

Contact Form

SPDT (1 Form C)

Contact Rating (current)

0.01A

Switching Voltage

30VAC, 30VDC - Max

Turn On Voltage (max)

9 VDC

Turn Off Voltage (min)

1.2 VDC

Features

Sealed - Fully

Contact Material

Copper (Cu), Gold (Au)

Operate Time

10ms

Release Time

10ms

Coil Power

200 mW

Operating Temperature

-40°C ~ 70°C

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

G6Z-1FE-ADC12

G6Z1FEADC12

G6Z1FEADC12

Safety Precautions

■ Precautions for Correct Use

Please observe the following precautions to prevent failure to

operate, malfunction, or undesirable effect on product performance.

High-frequency Characteristics Measurement Method

and Measurement Substrate

High-frequency characteristics for the G6Z are measured in the way

shown below. Consult your OMRON representative for details on

50-Ω models.

Measurement Method for 75-W Models

Through-hole Substrate (75-W Models, E-shape or Y-shape)

SMD-type Substrate (75-W Models, E-shape or Y-shape)

354

(Unit: mm)

40

(Unit: mm)

40

Network vector analyzer

(Agilent Technologies)

30

30

HP8753D

6.3

6.3

High-frequency Relay

50Ω/75Ω adapter

(Agilent Technologies)

11852B-004

0.4

1.4

40

30

40

30

0.4

1.4

G6Z

G6Z

4-dia. through-hole

0.6-dia. through-hole

4-dia. through-hole

0.6-dia. through-hole

3.59

3.91

1

1

75-Ω terminating

resistance

0.95

0.95

Substrate for High-frequency Characteristic Compensation

(75-W Models, E-shape or Y-shape)

Substrate Types

Material: FR-4 glass epoxy (glass cloth impregnated with epoxy

Thickness: 1.6 mm

Thickness of copper plating:18 μm

Note:

Note:

Note:

Note:

Note:

Handling

Do not use the Relay if it has been dropped. Dropping the Relay may

adversely affect its functionality.

Protect the Relay from direct sunlight and keep the Relay under nor-

mal temperature, humidity, and pressure.

Flow Soldering

Solder: JIS Z3282, H63A

Soldering temperature: Approx. 250°C (260°C if the DWS method is

used)

Soldering time: Approx. 5 s max. (approx. 2 s for the first time and

approx. 3 s for the second time if the DWS method is used)

Be sure to make a molten solder level adjustment so that the solder

will not overflow on the PCB.

40

(Unit: mm)

30

0.95

1. The compensation substrate is used when measuring the

2. For convenience, the diagrams of the high-frequency

3. Be sure to mount a standoff tightly to the through-hole

4. Use measuring devices, connectors, and substrates that

5. Ensure that there is no pattern under the Relay.

resin and copper laminated to its outer surface)

Relay’s insertion loss. The insertion loss is obtained by

subtracting the measured value for the compensation

substrate from the measured value with the Relay

mounted to the high-frequency measurement substrate.

measurement substrates given here apply both to models

with an E-shape terminal structure and to models with a

Y-shape terminal structure.

substrate.

are appropriate for 50 Ω and 75 Ω respectively.

Otherwise, the impedance may be adversely affected and

the Relay may not be able to attain its full characteristics.

1

30.7

20

4-dia. through-hole

0.6-dia. through-hole