LM20134EVAL National Semiconductor, LM20134EVAL Datasheet - Page 4

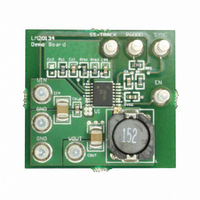

LM20134EVAL

Manufacturer Part Number

LM20134EVAL

Description

BOARD EVAL 4A POWERWISE LM20134

Manufacturer

National Semiconductor

Series

PowerWise®r

Specifications of LM20134EVAL

Main Purpose

DC/DC, Step Down

Outputs And Type

1, Non-Isolated

Voltage - Output

1.2V

Current - Output

4A

Voltage - Input

2.95 ~ 5.5V

Regulator Topology

Buck

Board Type

Fully Populated

Utilized Ic / Part

LM20134

Lead Free Status / RoHS Status

Not applicable / Not applicable

Power - Output

-

Frequency - Switching

-

www.national.com

Component Selection

This section provides a walk-through of the design process of

the LM20134 evaluation board. Unless otherwise indicated all

equations assume units of Amps (A) for current, Farads (F)

for capacitance, Henries (H) for inductance, and Volts (V) for

voltages.

INPUT CAPACITOR

The required RMS current rating of the input capacitor for a

buck regulator can be estimated by the following equation:

The variable D refers to the duty cycle, and can be approxi-

mated by:

From this equation, it follows that the maximum I

quirement will occur at a full 4A load current with the system

operating at 50% duty cycle. Under this condition, the maxi-

mum I

Ceramic capacitors feature a very large I

footprint, making a ceramic capacitor ideal for this application.

A 100 µF X5R ceramic capacitor from Murata with a 5.4A

I

evaluation board. For improved bypassing, a small 1 µF high

frequency capacitor is placed in parallel with the 100 µF bulk

capacitor to filter high frequency noise pulses on the supply.

AVIN FILTER

An RC filter should be added to prevent any switching noise

on PVIN from interfering with the internal analog circuitry con-

nected to AVIN. These can be seen on the schematic as

components R

of the resistor R

of current during startup, and if R

voltage drop can trigger the UVLO comparator. For the demo

board a 1Ω resistor is used for R

be triggered after the part is enabled. A recommended 1 µF

C

16dB of attenuation at the 1 MHz switching frequency.

INDUCTOR

As per the datasheet recommendations, the inductor value

should initially be chosen to give a peak to peak ripple current

equal to roughly 30% of the maximum output current. The

peak to peak inductor ripple current can be calculated by the

equation:

Rearranging this equation and solving for the inductance re-

veals that for this application (V

500 kHz, and I

roughly 1.52 µH. However, to allow evaluation of the

LM20134 over the full frequency range of operation a final

RMS

F

capacitor coupled with the 1Ω resistor provides roughly

rating provides the necessary input capacitance for the

CIN(RMS)

is given by:

F

F

OUT

and C

as the AVIN pin will draw a short 60mA burst

= 4A) the nominal inductance value is

F

. There is a practical limit to the size

F

IN

ensuring that UVLO will not

F

= 5V, V

is too large the resulting

RMS

OUT

rating in a small

= 1.2V, f

CIN(RMS)

SW

re-

=

4

inductance of 1.5 µH was selected. This results in a peak-to-

peak ripple current of 608 mA and 748 mA when the converter

is operating from 5V and 3.3V respectively. Once an induc-

tance value is calculated, an actual inductor needs to be

selected based on a tradeoff between physical size, efficien-

cy, and current carrying capability. For the LM20134 evalua-

tion board, a Coilcraft MSS1038-152NL inductor offers a good

balance between efficiency (8 mΩ DCR), size, and saturation

current rating (9A I

OUTPUT CAPACITOR

The value of the output capacitor in a buck regulator influ-

ences the voltage ripple that will be present on the output

voltage, as well as the large signal output voltage response

to a load transient. Given the peak-to-peak inductor current

ripple (ΔI

by the equation:

The variable R

pacitor. As can be seen in the above equation, the ripple

voltage on the output can be divided into two parts, one of

which is attributed to the AC ripple current flowing through the

ESR of the output capacitor and another due to the AC ripple

current actually charging and discharging the output capaci-

tor. The output capacitor also has an effect on the amount of

droop that is seen on the output voltage in response to a load

transient event.

For the evaluation board, a Murata 100 µF ceramic capacitor

is selected for the output capacitor to provide good transient

and DC performance in a relatively small package. From the

technical specifications of this capacitor, the ESR is roughly

2 mΩ, and the effective in-circuit capacitance is approximate-

ly 55 µF (reduced from 100 µF due to the 1.2V DC bias). With

these values, the peak to peak voltage ripple on the output

when operating from a 5V input can be calculated to be 3 mV.

C

A soft-start capacitor can be used to control the startup time

of the LM20134 voltage regulator. The startup time of the

regulator when using a soft-start capacitor can be estimated

by the following equation:

For the LM20134, I

board, the soft-start time has been designed to be roughly 5

ms, resulting in a C

C

The C

subregulator. This capacitor should be sized equal to or

greater than 1 µF, but less than 10 µF. A value of 1 µF is

sufficient for most applications..

C

The capacitor C

the LM20134 control loop. Since this board was optimized to

work well over the full input, output voltage, and frequency

range, the value of C

operating conditions for the device are known, the transient

SS

VCC

C1

VCC

P-P

capacitor is necessary to bypass an internal 2.7V

) the output voltage ripple can be approximated

ESR

C1

SAT

above refers to the ESR of the output ca-

is used to set the crossover frequency of

SS

SS

C1

capacitor value of 33 nF.

rating).

is nominally 5 µA. For the evaluation

was selected to be 4.7 nF. Once the