AFBR-59R5LZ Avago Technologies US Inc., AFBR-59R5LZ Datasheet - Page 4

AFBR-59R5LZ

Manufacturer Part Number

AFBR-59R5LZ

Description

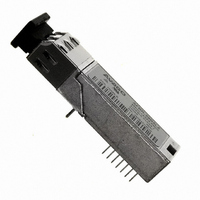

TXRX OPT SFF 4/2/1GBD 2X7

Manufacturer

Avago Technologies US Inc.

Datasheet

1.AFBR-59R5LZ.pdf

(20 pages)

Specifications of AFBR-59R5LZ

Data Rate

4.25GBd

Wavelength

850nm

Voltage - Supply

3.6V

Connector Type

LC

Mounting Type

Through Hole

Function

Digital Diagnostic SFP, supports high-speed serial links over multimode optical fiber.

Product

Transceiver

Maximum Rise Time

0.09 ns/0.15 ns

Maximum Fall Time

0.09 ns/0.15 ns

Pulse Width Distortion

0.06 ns (Max)/0.062 ns (Max)

Operating Supply Voltage

2.97 V to 3.63 V

Maximum Operating Temperature

+ 85 C

Minimum Operating Temperature

- 10 C

Package / Case

DIP With Connector

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Applications

-

Lead Free Status / Rohs Status

Lead free / RoHS Compliant

For Use With

Multimode Glass

Lead Free Status / RoHS Status

Lead free / RoHS Compliant, Lead free / RoHS Compliant

Other names

516-1995

Functional Data I/O

The AFBR-59R5LZ interfaces with the host circuit board

through fourteen I/O pins (2x7) identified by function

in Table 2. These pins are sized for the use in boards be-

tween 0.062 in. and 0.100 in. thick. The board layout for

this interface is depicted in Figure 7.

The AFBR-59R5LZ transmit and receive interfaces are

PECL compatible. To simplify board requirements,

transmitter bias resistors and ac coupling capacitors are

incorporated into the transceiver module and so are not

required on the host board. The Tx_Disable and Signal

Detect lines require TTL lines on the host board if they

are to be utilized. The transceiver will operate normally if

these lines are not connected on the host board.

Figure 2 depicts the recommended interface circuit to

link the AFBR-59R5LZ to the supporting physical layer

ICs. Timing for MSA compliant control signals imple-

mented in the transceiver are listed on Page 12 and

diagramed in Figure 5.

PCB Assembly Process Compatibility

The AFBR-59R5LZ is compatible with industry standard

wave solder and aqueous wash processes as detailed on

Page 13. The transceiver is shipped with a process plug

to keep out impinging liquids, but is not intended to be

immersed. After assembly, the process plug should be

kept in place as a dust plug when the transceiver is not

in use.

4

Caution

There are no user serviceable parts nor maintenance

requirements for the AFBR-59R5LZ. All mechanical

adjustments are made at the factory before shipping.

Tampering with, modifying, misusing or improperly han-

dling the AFBR-59R5LZ will void the product warranty.

It may also result in improper operation and possibly

overstress the laser source. Performance degradation

or device failure may result. Connection of the AFBR-

59R5LZ to a light source not compliant to IEEE 802.3 or

ANSI FC-PI specifications, operating above the maximum

operating conditions or in a manner inconsistent with it’s

design and function may result in exposure to hazardous

light radiation and may constitute an act of modifying or

manufacturing a laser product.

Persons performing such an act are required by law to

re-certify and re-identify the laser product under the

provisions of U.S. 21 CFR (Subchapter J) and the TUV.

Ordering Information

Please contact your local field sales engineer or one of

Avago Technologies franchised distributors for ordering

information. For technical information, please visit Ava-

go Technologies’ WEB page at www.avagotech.com or

contact Avago Technologies Customer Response Center

at 1-800-235-0312. For information related to SFF Com-

mittee documentation visit www.sffcommittee.org