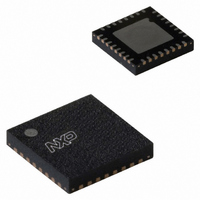

SC16C652BIBS,157 NXP Semiconductors, SC16C652BIBS,157 Datasheet - Page 40

SC16C652BIBS,157

Manufacturer Part Number

SC16C652BIBS,157

Description

IC UART DUAL W/FIFO 32HVQFN

Manufacturer

NXP Semiconductors

Datasheet

1.SC16C652BIB48128.pdf

(43 pages)

Specifications of SC16C652BIBS,157

Features

2 Channels

Number Of Channels

2, DUART

Fifo's

32 Byte

Voltage - Supply

2.5V, 3.3V, 5V

With Auto Flow Control

Yes

With Irda Encoder/decoder

Yes

With False Start Bit Detection

Yes

With Modem Control

Yes

With Cmos

Yes

Mounting Type

Surface Mount

Package / Case

32-VFQFN Exposed Pad

Transmitter And Receiver Fifo Counter

Yes

Data Rate

5Mbps

Operating Supply Voltage (max)

5.5V

Mounting

Surface Mount

Pin Count

32

Operating Temperature (min)

-40C

Operating Temperature (max)

85C

Operating Temperature Classification

Industrial

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Other names

568-2046

935276387157

SC16C652BIBS

935276387157

SC16C652BIBS

Philips Semiconductors

13. Abbreviations

SC16C652B_4

Product data sheet

[4]

[5]

[6]

[7]

[8]

[9]

Table 31:

Acronym

FIFO

UART

CPU

ISDN

DMA

These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the

solder cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink

on the top side, the solder might be deposited on the heatsink surface.

If wave soldering is considered, then the package must be placed at a 45 angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

Wave soldering is suitable for LQFP, QFP and TQFP packages with a pitch (e) larger than 0.8 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

Wave soldering is suitable for SSOP, TSSOP, VSO and VSSOP packages with a pitch (e) equal to or larger

than 0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

Image sensor packages in principle should not be soldered. They are mounted in sockets or delivered

pre-mounted on flex foil. However, the image sensor package can be mounted by the client on a flex foil by

using a hot bar soldering process. The appropriate soldering profile can be provided on request.

Hot bar soldering or manual soldering is suitable for PMFP packages.

Abbreviations

Description

First In, First Out

Universal Asynchronous Receiver/Transmitter

Central Processing Unit

Integrated Service Digital Network

Direct Memory Access

Rev. 04 — 1 September 2005

Dual UART with 32-byte FIFOs and IrDA encoder/decoder

© Koninklijke Philips Electronics N.V. 2005. All rights reserved.

SC16C652B

40 of 43