GPVOUS-0.040-00-0816 Bergquist, GPVOUS-0.040-00-0816 Datasheet - Page 14

GPVOUS-0.040-00-0816

Manufacturer Part Number

GPVOUS-0.040-00-0816

Description

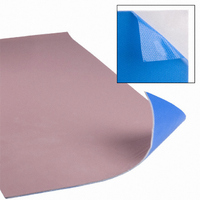

THERMAL PAD 8"X16" .040" GP US

Manufacturer

Bergquist

Series

Gap Pad® VOr

Datasheets

1.803129.pdf

(27 pages)

2.GPVOUS-0.020-00-0816.pdf

(1 pages)

3.GPVOUS-0.040-00-0816.pdf

(1 pages)

Specifications of GPVOUS-0.040-00-0816

Usage

Sheet

Shape

Rectangular

Outline

406.40mm x 203.20mm

Thickness

0.040" (1.02mm)

Adhesive

Tacky - One Side

Backing, Carrier

Fiberglass

Color

Pink

Thermal Conductivity

1.0 W/m-K

Packages Cooled

BGA

Operating Temperature Range

-60°C To +200°C

Length

16"

Overall Width

8"

Breakdown Voltage Vbr

6kV

Rohs Compliant

Yes

Lead Free Status / RoHS Status

Lead free / RoHS Compliant

Thermal Resistivity

-

Other names

.040 GP US 8"X16"

BER223

BG426651

BER223

BG426651

12

Base Metal Layer Design Considerations

t

t

The adjacent graph depicts the CTE of the base material in relationship

to the heat spreading capability of the metal. Although Aluminum and

Copper are the most popular base layers used in Thermal Clad, other

metals and composites have been used in applications where CTE mis-

match is a factor. The adjacent table represents standard and non-stan-

dard base layers.

Coefficient Of Thermal Expansion

And Heat Spreading

Coefficient Of Thermal Expansion

And Solder Joints

Solder joint fatigue can be minimized by selecting the correct base

layer to match component expansion. The major concern with ther-

mal expansion is the stress the solder joint experiences in power (or

thermal) cycling. Solder joints are not mechanically rigid. Stress

induced by heating and cooling may cause the joint to fatigue as it

relieves stress. Large devices, extreme temperature differential, badly

mismatched materials, or lead-free minimum solder thickness may all

place increased cyclic strain on solder joints.

Solder joint fatigue is typically first associated with ceramic based

components and with device termination. The section on “Assembly

Recommendations” (page 18-19) covers these issues in more detail.

Copper

Aluminum 5052

Aluminum 6061

Coefficient Of Thermal Expansion

And Heat Spreading

Coefficient Of Thermal Expansion

And Solder Joints

METAL / ALLOY

CONDUCTIVITY

THERMAL

[W/mK]

400

150

150

THERMAL EXPANSION

COEFFICIENT OF

[ppm/K]

17

25

25

t

t

t

t

Strength, Rigidity And Weight

Electrical Connections To Base Plate

Surface Finish

Costs

DENSITY

[g/cc]

8.9

2.7

2.7

Extra-Long Circuits

Finished circuits up to 25" (635mm) long

MODULUS OF

RIGIDITY

[GPa]

44.1

25.9

26

YIELD STRENGTH

[MPa]

310

215

230