203618-1 TE Connectivity, 203618-1 Datasheet - Page 63

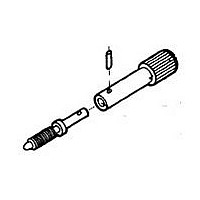

203618-1

Manufacturer Part Number

203618-1

Description

Connector Accessories Male Jack Screw Zinc Alloy

Manufacturer

TE Connectivity

Type

Jack Screw Kitr

Series

Mr

Specifications of 203618-1

Product Length (mm)

47.19mm

Product Depth (mm)

7.92mm

Product Diameter (mm)

7.92mm

Accessory Type

Jack Screw

Thread Size - Imperial

6-32

Screw Head Height

9.91mm

Screw Length

47.19mm

Screw Head Diameter

0.312"

Rohs Compliant

Yes

Angle

Straight

Brand/series

M Series

Length, Overall

1.858 "

Material, Housing

Zinc Alloy

Primary Type

Interconnect System

Product Type

Hardware

Gender

Male

Type Of Connector

Standard

Mount

Panel

Jackscrew Type

Turnable

Jackscrew Material

Zinc Alloy

Hardware Type

Jackscrew

Mounting Hardware

None

Jackscrew Style

Short

Jackscrew Coating

Clear Chromate

Jackscrew Tip, Roll Pin Material

Stainless Steel

Rohs/elv Compliance

RoHS compliant, ELV compliant

Lead Free Solder Processes

Not relevant for lead free process

Rohs/elv Compliance History

Always was RoHS compliant

Packaging Method

Loose Piece

Lead Free Status / RoHS Status

Compliant

For Use With

M Series Rectangular Connectors

Lead Free Status / Rohs Status

RoHS Compliant part

Catalog 82003

Revised 06-08

www.tycoelectronics.com

Dimensions are in millimeters

and inches unless otherwise

specified. Values in brackets are

equivalent U.S. Customary Units.

AMP M Series

Pin and Socket Connectors

M Series V.35 Special Application Connectors

Material Specifications

Contacts

The material composition and

construction of AMP Type III+

contacts encompasses vary-

ing price ranges and

performance characteristics.

Specific materials and avail-

able plating thicknesses of

each contact are provided.

Housings

M Series V.35 connector

housings are made of

general purpose phenolic

(black) or polyester (black).

Phenolic housings are

molded of material per

MIL-M-14, Type CFG. The per-

formance characteristics of

this material makes the con-

nector an excellent choice in

applications where excep-

tional resistance to acids,

alkalies, or solvents is not a

prime factor.

Hardware

A variety of materials such as

plated steel, stainless steel,

zinc (nickel plated) and alu-

minum are used in the

manufacture of M Series V.35

connector hardware. This

provides for the proper oper-

ation and durability of each

hardware component, while

offering a choice of econo-

mies to satisfy partic-

ular application

requirements.

Dimensions are shown for USA: 1-800-522-6752

reference purposes only.

Specifications subject

to change.

Current Carrying

Capabilities

The total current capacity

of each contact in any given

M Series connector is depen-

dent upon the heat rise

resulting from the combina-

tion of electrical loads of all

contacts in the connector

arrangement and the maxi-

mum ambient temperature in

which the connector will be

operating. Caution must be

taken to insure that this com-

bination of conditions does

not cause the internal tem-

perature of the connector to

exceed the maximum operat-

ing temperature of the

housing material. Several vari-

ables which must be

considered when determining

this maximum current capa-

bility for your application are:

a) Wire Size - Larger wire

b) Connector Size - In

c) Current Load Distribution -

d) Ambient Temperature -

will carry more current

since it has less internal

resistance to current flow

and generates less heat.

The wire also conducts

heat away from the

connector.

general, with more

circuits in a connector,

less current per contact

can be carried.

Spreading those lines

with greater current loads

throughout the connector,

particularly around the

outer perimeter, will

enhance heat dissipation.

With higher ambient

temperature, less

current can be carried.

Canada: 1-905-470-4425

Mexico: 01-800-733-8926

C. America: 52-55-5-729-0425 UK: 44-141-810-8967

NOTE: All part numbers

are RoHS Compliant

Performance Data

Temperature Rating -

Phenolic Housings, -55°C to

+150°C

Polyester Housings -

–55°C to +130°C

Flammability Rating -

Phenolic Material, UL 94V-0

Dielectric Withstanding

Voltage (at sea level)

Type III+ Contacts, 900 VAC,

RMS

Durability (Mating/Unmating)

- Contacts, Gold plated -

500 cycles; Contacts, Bright

tin-lead plated - 50 cycles

Note: For detailed information on

the above performance data and

further information on other perfor-

mance data such as Insulation

Resistance, Thermal Shock, Moisture

Resistance, Vibration and Physical

Shock, request AMP Product

Specification No. 108-10001.

South America: 55-11-3611-1514

Hong Kong: 852-2735-1628

Japan: 81-44-844-8013

(Continued)

63